Manual filling machines: A powerful tool for production, supporting the upgrading of the manufacturing industry

In the manufacturing industry, filling machines are indispensable equipment, capable of dispensing liquid or semi-liquid products into containers to meet various production needs. Manual filling machines, as a member of the filling machine family, have unique advantages that make them a valuable asset in certain specific production scenarios. This article will delve into manual filling machines, exploring their characteristics, working principles, application scenarios, and existing problems and solutions.

Firstly, manual filling machines offer the advantages of high production efficiency and simple operation. Compared to automatic filling machines, manual filling machines do not require complex pneumatic or electric systems; the filling process is completed through simple manual operation. This makes them particularly flexible in small-batch, multi-variety production processes. Furthermore, manual filling machines require minimal operator skill, allowing for easy operation after simple training, significantly reducing labor costs for businesses.

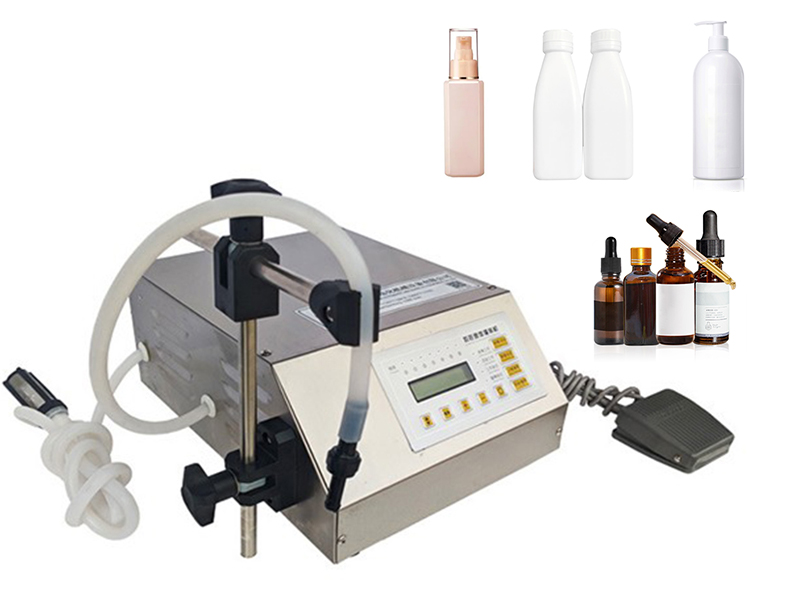

Next, let's examine the working principle and components of a manual filling machine in detail. A manual filling machine primarily consists of a filling head, a metering device, a cylinder, and a conveyor belt. The filling head is the core component, responsible for dispensing the liquid or semi-liquid product into the container. The metering device controls the filling volume, while the cylinder provides the power to drive the filling head for the filling operation. The conveyor belt transports the containers to the designated position, completing the entire filling process.

In terms of application scenarios, manual filling machines are widely used in numerous industries, including pharmaceuticals, food, and daily chemical products. For example, in the pharmaceutical industry, manual filling machines are often used for filling liquid products such as medicines and reagents; in the food industry, they are used for filling semi-liquid products such as condiments and edible oils; and in the daily chemical industry, manual filling machines are used for filling products such as shampoos and shower gels.

However, manual filling machines also have some drawbacks. Firstly, due to their manual operation, they require significant physical effort from the operator, leading to fatigue during prolonged use. Secondly, the production efficiency of manual filling machines is relatively low, making them unsuitable for large-scale production. To address these issues, the following measures can be taken:

Equipment maintenance and upkeep: To ensure the normal operation of manual filling machines, companies need to develop corresponding equipment maintenance and upkeep plans. Regular cleaning, lubrication, and inspection of the equipment will extend its service life and reduce the failure rate.

Optimizing operating procedures: By optimizing operating procedures, the physical strain on operators can be reduced. For example, the layout of the conveyor belt can be improved so that operators do not need to frequently bend down or lift heavy objects.

Adding automation elements: Although manual filling machines primarily rely on manual operation, companies can try to introduce some automation elements to improve production efficiency. For example, photoelectric sensors and counters can be added to achieve automatic control and counting functions.

Improving operator skills: Strengthen the skills training of operators so that they can skillfully master the operating techniques and precautions of manual filling machines. This will not only improve production efficiency but also reduce safety risks caused by improper operation.

In short, manual filling machines, as a flexible and practical filling equipment, play an irreplaceable role in enterprise production. By understanding the characteristics, working principles, application scenarios, and existing problems and solutions of manual filling machines, companies can better select and use manual filling machines, improve production efficiency and reduce costs, and contribute to the upgrading and development of the manufacturing industry.