Chemical liquid filling machines: Essential equipment for production efficiency and quality.

In the chemical industry, liquid filling machines are indispensable equipment. Their main function is to fill liquid raw materials or products according to specific quantities and specifications. Chemical liquid filling machines have a wide range of applications in many fields, such as food, pharmaceuticals, and detergents. This article will delve into the importance and application scenarios of chemical liquid filling machines, as well as precautions to be taken during their use.

1. Basic Concepts of Chemical Liquid Filling Machines

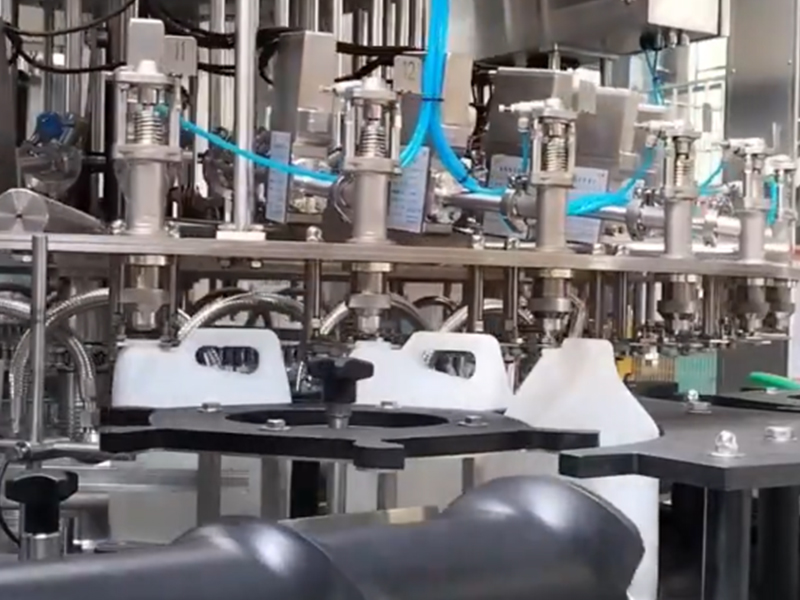

A chemical liquid filling machine is a machine specifically designed for filling liquids. It can automatically fill liquid raw materials or products into designated containers. Chemical liquid filling machines typically consist of a filling head, a control system, and a robotic arm, and are characterized by automation, high efficiency, and precision.

2. Advantages of Chemical Liquid Filling Machines

Increased production efficiency: Chemical liquid filling machines can complete filling operations quickly and accurately, greatly improving production efficiency. Compared to manual filling, chemical liquid filling machines can reduce labor costs and minimize errors caused by manual operation.

Reduced costs: Chemical liquid filling machines utilize mechanical automation technology, which reduces labor costs. At the same time, the high efficiency of the filling process also reduces energy consumption, lowering production costs for enterprises.

High safety and reliability: Chemical liquid filling machines are designed with safety in mind and are equipped with various safety protection devices. During the filling process, if an abnormal situation occurs, the machine will automatically stop working to prevent accidents.

3. Application Scenarios of Chemical Liquid Filling Machines

Food industry: In the food industry, chemical liquid filling machines are widely used for filling beverages, condiments, edible oils, and other products. Chemical liquid filling machines ensure the hygiene and safety of food, improve production efficiency, and reduce costs.

Pharmaceutical industry: In the pharmaceutical industry, chemical liquid filling machines are mainly used for filling pharmaceutical raw materials. High-precision chemical liquid filling machines ensure accurate dosage of pharmaceutical raw materials, improving the quality and efficiency of pharmaceutical production.

Detergent industry: In the detergent industry, chemical liquid filling machines are used to fill various detergent products. Chemical liquid filling machines can achieve efficient and accurate filling, helping detergent manufacturers increase production and reduce costs.

4. Precautions for using chemical liquid filling machines

Maintain hygiene: To ensure product quality and safety, it is important to maintain cleanliness and hygiene when using chemical liquid filling machines. Regularly clean and disinfect the equipment to avoid product quality issues caused by hygiene problems.

Regular maintenance: Chemical liquid filling machines require regular maintenance during use to check that all parts of the machine are working properly. Regular maintenance extends the service life of the machine.

Use safety protection measures: When operating chemical liquid filling machines, appropriate safety protective equipment should be worn, such as protective gloves and safety glasses. This ensures that accidents are avoided during operation.

This article, through practical examples, elaborates on the importance and application scenarios of chemical liquid filling machines in the chemical industry. Chemical liquid filling machines have advantages such as improved production efficiency, reduced costs, and high safety and reliability, and are therefore widely used in food, pharmaceuticals, detergents, and other fields. When using chemical liquid filling machines, it is essential to pay attention to maintaining equipment hygiene, regular maintenance, and using safety protection measures. Only in this way can the advantages of chemical liquid filling machines be fully utilized, improving the production efficiency and competitiveness of enterprises.