Visual automation equipment: Leading the future development of manufacturing.

With the continuous advancement of technology, visual automation equipment has become an important tool in the manufacturing sector. It utilizes advanced vision technology to perceive and analyze images by simulating the human eye, thereby achieving functions such as automated detection, recognition, and positioning. This article will provide a detailed introduction to visual automation equipment, covering its definition, types, application areas, advantages, and future development trends.

I. Definition of Visual Automation Equipment

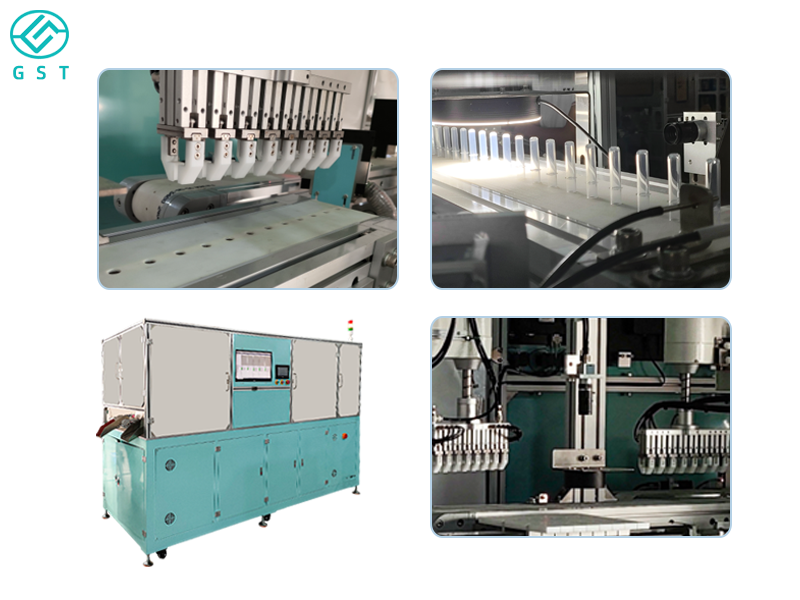

Visual automation equipment refers to a system that uses computer vision technology, combined with robots, manipulators, and other equipment, to achieve automated detection, recognition, and positioning functions in the manufacturing process. It is characterized by high efficiency, accuracy, and intelligence, and can process large amounts of data in a short time, improving production efficiency and product quality.

II. Types of Visual Automation Equipment

Visual automation equipment can be divided into the following types based on its application scenarios and functions:

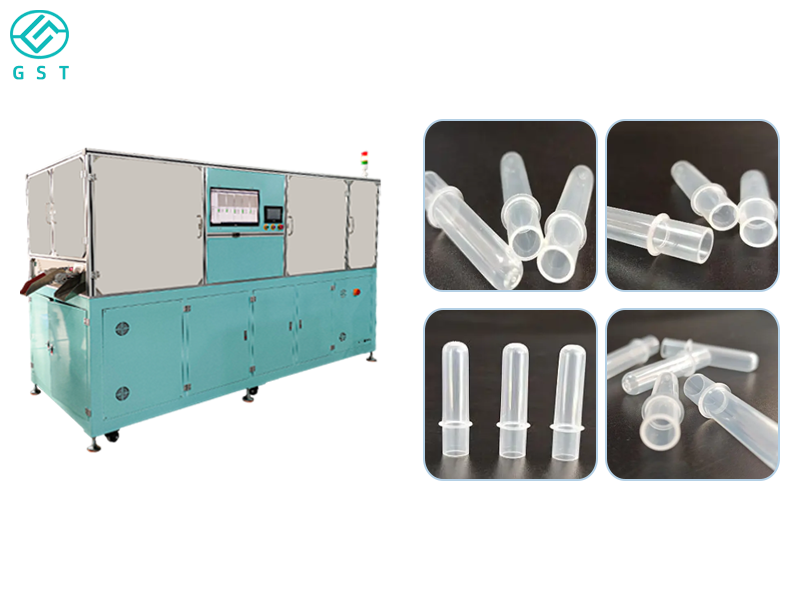

Visual inspection equipment: Used to detect defects, dimensions, colors, and other characteristics of product surfaces, such as glass product inspection and surface defect detection.

Visual recognition equipment: Used to identify markings, characters, barcodes, etc., on products, such as part recognition and packaging label recognition.

Visual positioning equipment: Used to accurately locate the position and orientation of products, such as for robot grasping and assembly.

III. Application Areas of Visual Automation Equipment

Visual automation equipment is widely used in industrial fields such as automotive manufacturing, electronics manufacturing, semiconductor manufacturing, and pharmaceutical manufacturing, as well as in public sectors such as logistics and security inspection. Its main functions include automated detection, recognition, and positioning, significantly improving production efficiency and product quality.

IV. Advantages of Visual Automation Equipment

Compared with traditional manual inspection, recognition, and positioning, visual automation equipment has the following advantages:

Improved production efficiency: Visual automation equipment can quickly and accurately complete detection, recognition, and positioning tasks, greatly improving production efficiency.

Reduced labor costs: The use of visual automation equipment reduces manual operations and labor costs, improving the competitiveness of enterprises.

Improved product quality: Visual automation equipment can accurately detect, recognize, and position products, avoiding errors caused by human factors and improving product quality. Reduced Labor Intensity: Traditional manual inspection, identification, and positioning tasks require prolonged staring at products, which can easily lead to visual fatigue and physical strain. Visual automation equipment reduces visual fatigue and physical strain on workers, improving work efficiency and overall health.

V. Future Development Trends

With the continuous advancement of technology and the ever-changing market demands, visual automation equipment will face more development opportunities and challenges. In the future, visual automation equipment will develop in the following directions:

Intelligentization: Visual automation equipment will become more intelligent, capable of adapting to different workpieces and environments, improving the autonomy and intelligence of the equipment.

High Efficiency: Visual automation equipment will become more efficient, able to complete detection, identification, and positioning tasks faster, further improving production efficiency.

Precision: Visual automation equipment will become more precise, able to more accurately detect, identify, and position products, improving product quality and accuracy.

Integration: Visual automation equipment will become more integrated, able to seamlessly connect with other equipment and technologies, achieving the integration and automation of production lines.

In short, visual automation equipment is an important tool in the manufacturing field, with broad application prospects and huge market potential. In the future, with the continuous advancement of technology and the ever-changing market demands, visual automation equipment will face more development opportunities and challenges, making greater contributions to innovation and development in the manufacturing field.