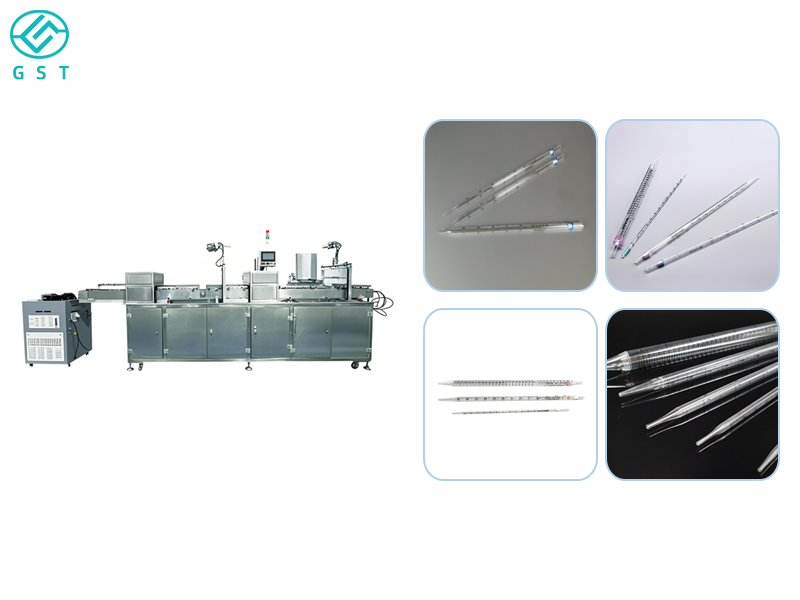

Automatic Dual-Color Pipette Printing Machine: A New Standard for High-Precision Marking of Laboratory Consumables

To ensure clear markings, accurate labeling, and distinct color differentiation during use, more and more companies are adopting dual-color screen printing technology for high-precision marking of pipettes. The core equipment enabling this efficient and stable process is the automatic dual-color pipette screen printing machine. As a leading brand in the field of intelligent equipment for laboratory consumables in China, GST, with its independently developed fully automatic dual-color screen printing solution, is helping the industry move towards a new era of high-efficiency, high-consistency, and high-compliance labeling.

Traditional single-color screen printing or manual labeling methods suffer from problems such as single color, easy peeling, and inaccurate positioning, making it difficult to meet the high standards required for color coding (e.g., red representing 1mL, blue representing 5mL) and dual scale lines on multi-specification and multi-purpose pipettes. The automatic dual-color pipette screen printing machine, through two precise overprints, can achieve clear, durable, and non-offset printing of two colors on the same pipette, not only improving product identification but also complying with international medical consumable labeling standards (such as ISO 15223 and FDA 21 CFR Part 820).

More importantly, the automated equipment can achieve high-speed printing of 60-120 pipettes per minute. Combined with an integrated process of automatic feeding, positioning, drying, and unloading, it significantly reduces labor costs, eliminates human error, and ensures high consistency in product labeling for every batch.

GST has been deeply involved in the field of automated equipment for laboratory consumables for many years, and has developed an industry-leading automatic dual-color pipette screen printing machine to address the special printing needs of products such as pipettes, pipette tips, and centrifuge tubes. This device boasts the following core advantages:

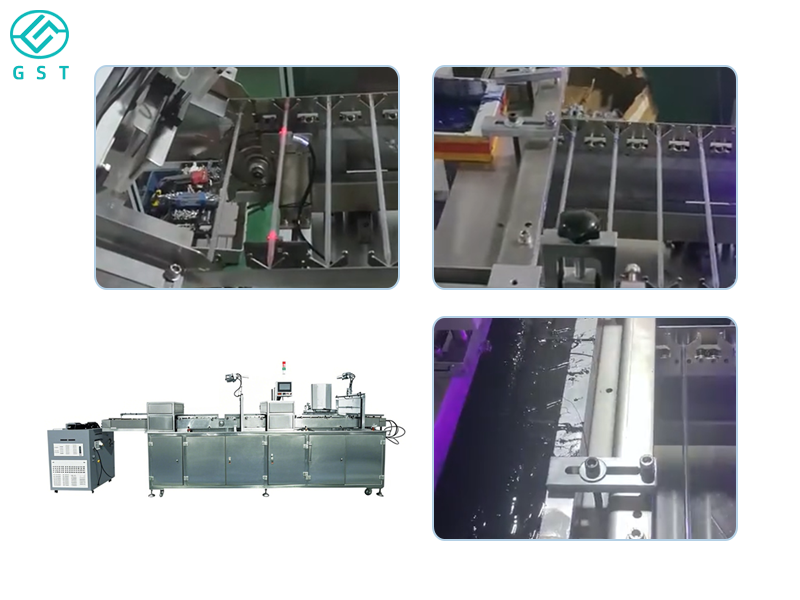

High-precision dual-color printing system: Utilizing servo motor and high-resolution encoder control, the printing accuracy reaches ±0.05mm, ensuring precise alignment of dual-color scale lines;

Intelligent visual positioning: Built-in CCD visual recognition module automatically corrects pipette angle and position, adapting to different diameters and transparencies of pipette tubes;

Environmentally friendly UV curing technology: Supports fast-drying environmentally friendly inks, combined with UV LED instant curing, resulting in no solvent volatilization and meeting green production requirements;

Flexible production design: Allows for quick switching between various pipette specifications from 1mL to 50mL, and supports customized printing of logos, barcodes, QR codes, and other composite information;

Fully enclosed clean structure: The entire machine meets ISO Class 8 (Class 100,000) cleanroom standards, suitable for medical-grade consumable production lines.

Currently, GST's automatic dual-color pipette screen printing machine has been widely used by well-known domestic and international biological consumable manufacturers and successfully exported to Germany, South Korea, Singapore, and other countries, earning high customer trust with its stable performance and localized technical services.

In industries with extremely high demands for experimental accuracy, such as life sciences, in vitro diagnostics (IVD), and biopharmaceuticals, pipettes are not only basic consumables but also critical carriers for experimental data traceability and operational safety. Pipettes are no longer just simple tools, but precision components that carry data, safety, and brand value. Choosing an efficient and reliable automatic dual-color pipette screen printing machine is a crucial step for companies to enhance product added value, obtain international certifications, and expand into high-end markets.