Automatic screen printing machines for centrifuge tubes improve overall production efficiency

With the continuous development of the biopharmaceutical, in-vitro diagnostics, and laboratory consumables industries, the clarity and consistency of markings on centrifuge tubes, as a basic laboratory consumable, are becoming increasingly important. Automatic centrifuge tube screen printing machines, with their advantages of high efficiency, high consistency, and high degree of automation, are gradually becoming essential equipment for centrifuge tube manufacturers to enhance product added value and brand image.

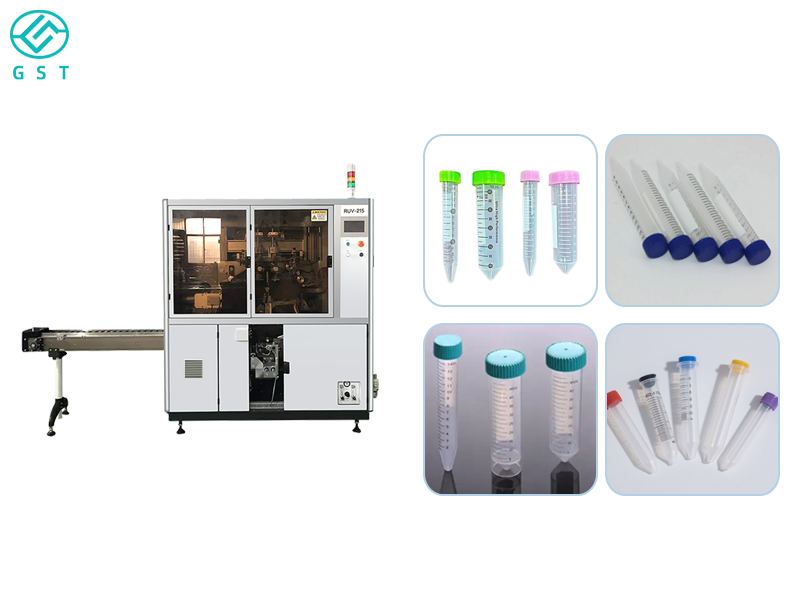

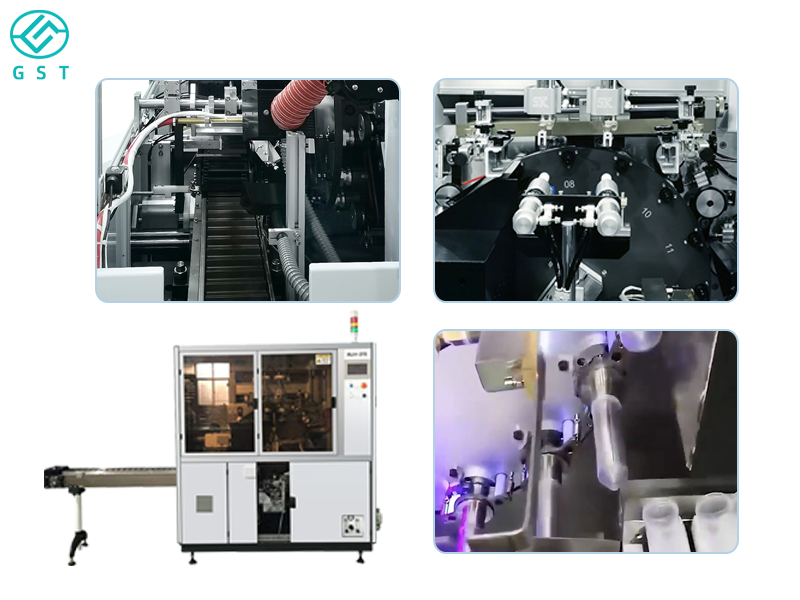

The automatic centrifuge tube screen printing machine is primarily used for automatically screen printing scales, text, logos, and other information on the surface of centrifuge tubes. The equipment utilizes a precise positioning and synchronization control system to achieve continuous operation of automatic feeding, positioning, screen printing, curing, and finished product output, effectively avoiding deviations caused by manual operation and ensuring consistent printing positions and clear patterns on every centrifuge tube.

In terms of production efficiency, the automatic centrifuge tube screen printing machine can achieve high-speed and stable operation, suitable for large-scale continuous production. Compared with traditional manual screen printing methods, automated equipment not only significantly increases output per unit time but also substantially reduces labor costs and management pressure, helping companies maintain a cost advantage in fierce market competition. At the same time, the stable operation of the equipment facilitates long-term continuous production, meeting the production needs of concentrated orders.

From the perspective of printing quality, the automatic centrifuge tube screen printing machine adopts a mature screen printing process, with strong ink adhesion, wear resistance, and clear and durable scales and markings that are not easily detached. This meets the requirements of repeated use in laboratories and complex working conditions such as high temperature and centrifugation. This is of great significance for improving the user experience and product quality of centrifuge tubes, and also helps companies establish a professional and reliable brand image.

As the industry's requirements for production standards and product traceability increase, the design of automatic centrifuge tube screen printing machines places greater emphasis on stability and ease of maintenance. The equipment has a reasonable structure, reliable selection of key components, and supports rapid changeover for multiple specifications of centrifuge tubes, allowing for flexible adaptation to different customer needs. At the same time, the entire machine can be seamlessly integrated with automated centrifuge tube production lines, achieving online and automated screen printing processes and further improving overall production efficiency.

From the perspective of long-term corporate development, introducing high-performance automatic centrifuge tube screen printing machines can not only improve production efficiency and printing quality but also contribute to product standardization and brand differentiation. With the continuous improvement of automation and intelligence levels, automatic screen printing machines for centrifuge tubes will play an increasingly important role in the production of laboratory consumables, creating a sustainable competitive advantage for businesses.