Automation production lines are at the core of enterprise transformation and upgrading

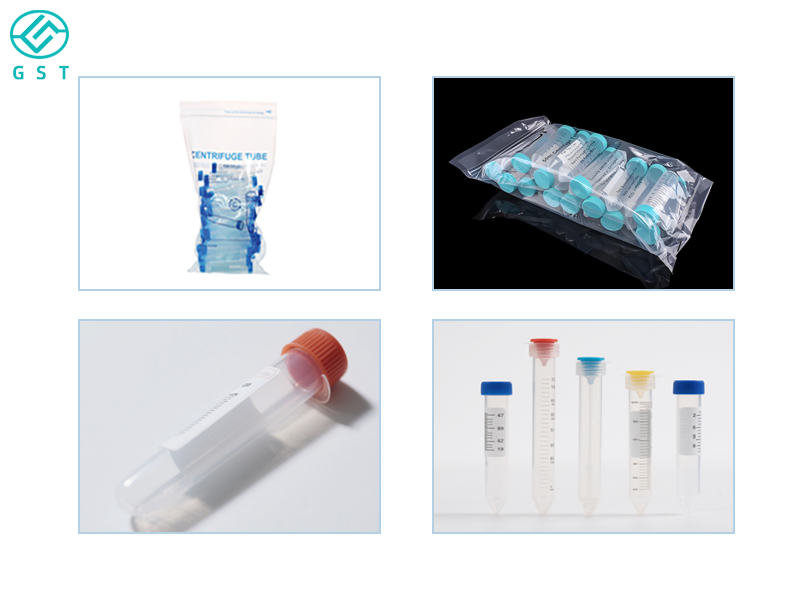

Against the backdrop of rapid development in the biopharmaceutical, in-vitro diagnostics, and laboratory consumables industries, centrifuge tubes, as one of the basic and frequently used consumables, are experiencing continuously growing market demand. Traditional manual or semi-automatic production methods are no longer sufficient to meet the requirements of high capacity, high consistency, and high cleanliness. Therefore, automated centrifuge tube production lines have become a core choice for many manufacturers seeking transformation and upgrading. By introducing automated and intelligent equipment, companies can significantly improve production efficiency and product quality, enhancing their market competitiveness.

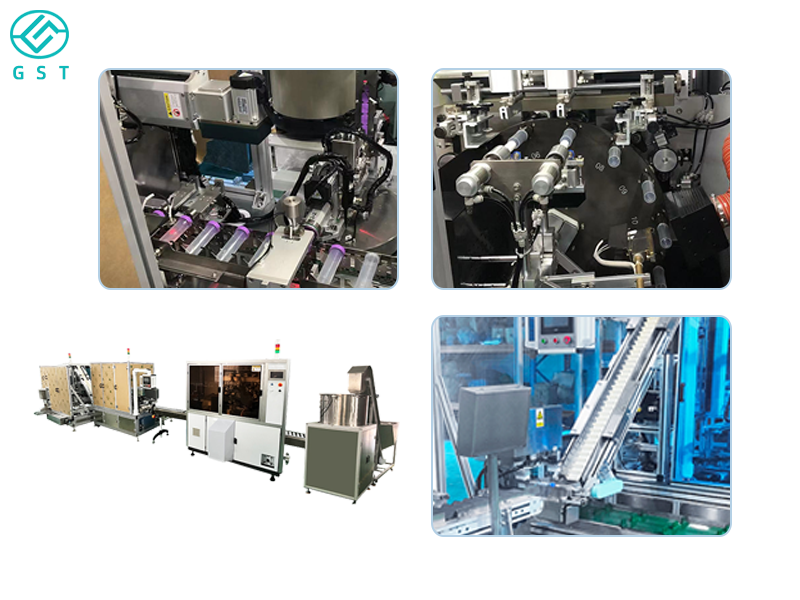

A centrifuge tube automated production line typically encompasses multiple processes, including injection molding, online inspection, automatic assembly, capping, filling, labeling, and finished product output, achieving continuous production from raw materials to finished products. Automatic transfer and intelligent control systems connect each workstation, effectively reducing manual intervention and minimizing errors and contamination risks associated with human operation. This is particularly suitable for the production of medical and laboratory consumables that require high cleanliness and consistency.

In terms of production efficiency, automated centrifuge tube production lines can achieve high-speed and stable operation, running continuously for 24 hours, significantly increasing output per unit of time. A mature automated production line can often replace multiple traditional semi-automatic production lines, not only saving significant labor costs but also helping companies maintain stable delivery capabilities during periods of concentrated orders or market demand fluctuations, laying the foundation for large-scale operations.

Product quality is a critical indicator in centrifuge tube production. Automated centrifuge tube production lines ensure precise assembly and stable and reliable sealing performance through high-precision assembly and online inspection technologies. Some production lines can also be equipped with automatic leak detection and visual inspection functions to monitor and eliminate appearance defects and assembly anomalies in real time, effectively improving the finished product pass rate and reducing after-sales risks.

With increasingly stringent industry regulations, the standardization and traceability of the production process are becoming more important. Modern automated centrifuge tube production lines are designed with cleanliness requirements in mind. The entire machine often uses stainless steel and food-grade/medical-grade materials, with a simple and easy-to-clean structure, complying with relevant quality management system requirements. At the same time, the automated control system can record key production data, providing strong support for quality traceability and production management. In practical applications, different companies have varying needs regarding centrifuge tube specifications, production capacity, and functional configurations. Customization capabilities have become a crucial criterion for evaluating the strength of equipment suppliers. GST, with its deep expertise in the field of automation equipment, has accumulated rich experience in the overall planning, equipment manufacturing, and system integration of automated centrifuge tube production lines. They can provide stable, efficient, and scalable solutions based on customers' actual needs, helping companies quickly achieve automation upgrades.

From a long-term perspective, building a high-level automated centrifuge tube production line not only improves current production efficiency and product quality but is also a crucial step for companies to adapt to industry trends and build core competitiveness. With the continuous expansion of the biopharmaceutical and laboratory consumables market, automated centrifuge tube production lines will play an increasingly important role in the future, creating broader development opportunities for businesses.