Automatic Plastic Seal Packaging Machine: Efficient, Precise and Environmentally Friendly Packaging Choice

As an important equipment in the field of automated packaging, automatic plastic seal packaging machine has become one of the first choices in the modern packaging industry by virtue of its high efficiency, precision and energy saving features. With the continuous development of industrialization and automation technology, the quality requirements of various types of product packaging is also gradually improved, and the plastic sealing packaging machine was born, especially suitable for food, medicine, cosmetics, electronic components, industrial products and other fields of application.

First, the working principle of automatic plastic sealing packaging machine

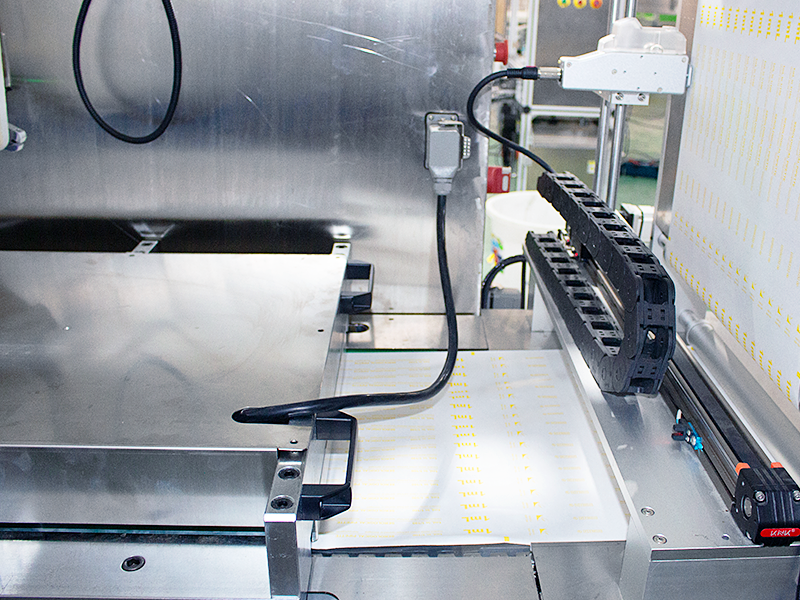

The core working principle of automatic plastic sealing packaging machine is based on heat sealing and pressure molding technology, through heating and appropriate pressure, the plastic film will be laminated to the product surface to achieve product encapsulation. A typical automatic plastic sealing packaging machine consists of feeding system, molding device, sealing device, cooling system and discharge system. The workflow is roughly as follows:

1. Feeding stage: The machine conveys the products to be encapsulated to the molding area to ensure proper positioning of the products.

2. Plastic sealing film supply: the automatic feeding system conveys the film to the encapsulation area.

3. Heat sealing and pressure molding: Under the action of appropriate temperature and pressure, the film is firmly wrapped around the product surface.

4. Cooling and discharging: After the encapsulation is completed, the packaging effect is fixed by a cooling system, and the packaged products are subsequently output by a conveyor belt.

This encapsulation is not only easy to operate, but also sealing effect is good, effectively preventing air, moisture into the product, to ensure that the contents of the package from outside pollution and influence.

Second, the advantages of automatic plastic packaging machine

1. High efficiency: automatic plastic sealing packaging machine is fast and easy to operate, greatly improving the packaging efficiency. Compared with traditional manual operation, the automation system can complete a large number of packaging tasks in a short time, reduce manual operation and improve the efficiency of the production line.

2. Precision and consistency: automated equipment can maintain the accuracy of the size and sealing position of each package, thus ensuring consistent packaging results. This precise control also reduces the waste of packaging materials, making the production cost effectively controlled.

3. Environmental protection and energy saving: modern automatic plastic sealing packaging machine mostly adopts energy-saving design, which not only reduces the energy consumption of the machine, but also reduces the generation of waste, which helps to realize green production.

4. Reduce labor intensity: automated packaging equipment can work continuously without frequent manual intervention, reducing the labor intensity of employees, while reducing the errors and risks that may result from manual operation.

5. Strong adaptability: automatic plastic sealing packaging machine usually supports different specifications and types of packaging needs, and can adapt to the packaging requirements of a variety of products. This makes it flexible to adapt to the packaging specifications of different products, especially suitable for enterprises with diverse production needs.

Third, the field of application

Automatic plastic seal packaging machine is widely used in many industries:

-Food industry: automatic plastic seal packaging machine is especially widely used in the food industry, especially for products with high shelf life requirements (such as cookies, potato chips, etc.). Plastic sealing packaging can effectively isolate the air and extend the shelf life of food.

-Pharmaceutical industry: In the pharmaceutical field, many drugs need to be preserved to isolate the air and moisture, the plastic seal packaging machine plays a protective role in the packaging of pharmaceutical products, to protect the quality and safety of drugs.

-Cosmetic industry: automatic plastic seal packaging machine is widely used in the packaging of cosmetics to ensure the stability and safety of cosmetics in transportation and storage.

-Electronic industry: automatic plastic sealing packaging machine for electronic components can prevent the product moisture or oxidation, to extend its service life.

Fourth, the maintenance of automatic plastic sealing packaging machine

In order to ensure the normal operation of the automatic sealing packaging machine and extend the service life, routine maintenance is very important. The following are several key maintenance measures:

1. Regular cleaning: clean the sealing heating area to ensure that there is no residue to avoid sealing is not solid. Also, clean the conveyor belt regularly to ensure its proper functioning.

2. Lubricate and maintain: Regularly check and lubricate the moving parts of the machine to ensure smooth operation and prolong the service life of the machine.

3. Check the electrical system: Since the machine is operated by electrical control, check the electrical system regularly to ensure that the lines are connected reliably and avoid stopping due to electrical faults.

4. Regular replacement of wearing parts: some key components of the plastic sealing packaging machine will be lost after long-term use, such as heat sealing tape, gasket, etc.. Timely replacement of these wearing parts can effectively protect the sealing quality and operational stability of the packaging machine.

With the increasing complexity and diversification of packaging needs, the technology of automatic plastic sealing packaging machine is also progressing. In the future, intelligent, high-speed and high-precision, environmentally friendly plastic sealing packaging machine will become the mainstream. Especially in the environment of Industry 4.0, the plastic sealing packaging machine will be more integrated into the intelligent system to further improve the production efficiency and packaging effect, and reduce costs.

Overall, automatic plastic sealing packaging machine has become one of the indispensable equipment for modern production enterprises. It not only meets the needs of enterprises for efficient packaging, but also saves a lot of labor costs and material costs for enterprises. With the continuous development of automation technology, the application range of automatic plastic sealing packaging machine will be further expanded, providing more efficient, stable and economical packaging solutions for the production of various industries.