Automatic labeling packaging machine features, applications and advantages of analysis

With the modernization of production efficiency and packaging precision needs continue to improve, automatic labeling packaging machine has gradually become one of the indispensable equipment in many industries. Automatic labeling packaging machine is a set of automatic labeling, packaging as one of the intelligent equipment, it can be in different shapes and materials of the product surface for efficient and accurate labeling operations, for the production of enterprises to provide efficient and consistent packaging solutions. In this paper, we will discuss in detail the characteristics of automatic labeling packaging machine, application areas and its advantages in modern production.

First, the characteristics of automatic labeling packaging machine

1. High-precision labeling: automatic labeling packaging machine is equipped with advanced control systems and sensors, can accurately control the labeling position and angle, so as to ensure the accuracy and consistency of labeling. For products requiring high precision, especially in the pharmaceutical, food and electronics industries, the fully automatic labeling packaging machine can achieve millimeter-level accuracy to ensure the stability and aesthetics of labeling.

2. High-speed operation: automatic labeling packaging machine adopts high-speed servo motor and synchronous drive technology, so that it has the ability to fast labeling. Labeling speed and packaging line speed can reach hundreds per minute, to adapt to the needs of mass production, while reducing the operating time and labor costs.

3. Flexibility and adaptability: automatic labeling packaging machine can be applied to different shapes of products, such as round bottles, square boxes, flat boxes, plastic bags and so on. In addition, the equipment can adjust the size and position of the label to meet the needs of different products and packaging specifications. This flexibility allows the equipment to quickly switch in the production line to adapt to diverse production needs.

4. Intelligent control system: modern automatic labeling packaging machine is generally equipped with a touch screen control system and PLC programming control, the operator can set the labeling parameters and monitoring through the human-machine interface. The intelligent system can also real-time detection of equipment status, to ensure the normal operation of the production line. At the same time, it also supports data statistics and historical records query, providing data support for production management.

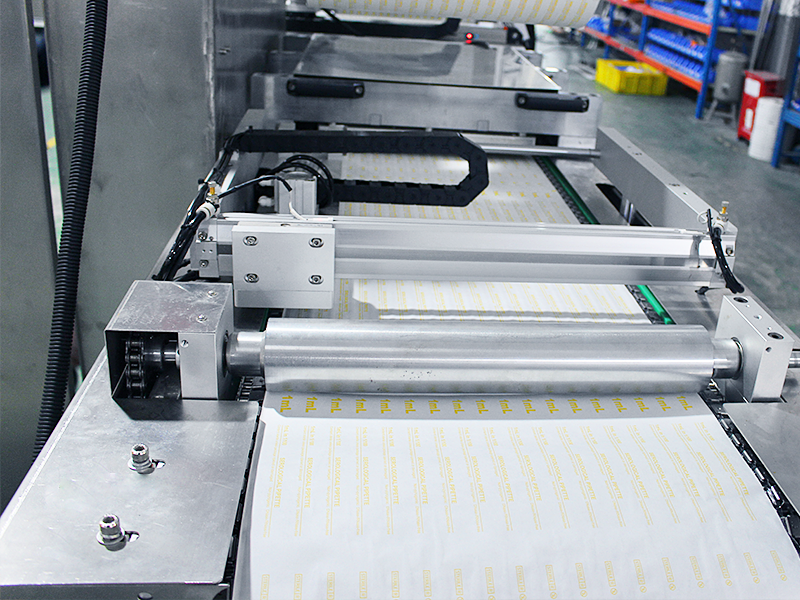

5. Stability and durability: the automatic labeling packaging machine adopts high-quality stainless steel and aluminum alloy structure, which can adapt to the high-intensity industrial environment for a long time. In addition, the equipment is designed to take into account factors such as heat dissipation and shock resistance, so that it can operate stably for a long time, reducing downtime and maintenance costs.

Second, the main application areas of automatic labeling packaging machine

Automatic labeling packaging machine has been widely used in the following areas:

1. Food industry: food packaging has strict requirements for hygiene and aesthetics. Automatic labeling packaging machine can achieve fast and accurate labeling, to ensure that the label information is accurate and in line with health standards. At the same time, the equipment can also adapt to a variety of packaging forms in the food industry, such as bottles, cans, boxes, etc., to help food manufacturers to improve production efficiency.

2. Pharmaceutical industry: the accuracy and clarity of the drug packaging labeling information is particularly important. Automatic labeling packaging machine in the pharmaceutical field is widely used in medicine bottles, boxes and other packaging labeling operations. As the packaging of pharmaceutical products usually need to include the production date, expiration date, ingredients and other information, the equipment also supports automatic coding and coding functions to ensure that the information of pharmaceutical products is accurate.

3. Daily chemical industry: in the packaging process of cosmetics, detergents and other daily chemical products, the appearance of the aesthetics of the brand image is critical. Automatic labeling packaging machine can be different shapes of bottles, bags and other beautiful and neat labeling, and labeling position is accurate, firm, so as to meet the high standards of daily chemical products packaging needs.

4. Electronic products industry: electronic products in the packaging usually with a variety of bar codes, two-dimensional code and other information. Automatic labeling packaging machine can realize high-precision labeling on the packaging line, and ensure that the bar code or two-dimensional code can be scanned, which is convenient for product traceability management. In addition, the equipment can also support self-adhesive, electrostatic film and other different materials of the label, to adapt to the special requirements of electronic products.

5. Chemical industry: the packaging of chemical products often have special protection and labeling requirements, such as warning labels for hazardous chemicals. Automatic labeling packaging machine can work properly in the complex chemical environment, to ensure that the label is firmly affixed and clarity, to provide protection for the safe use of chemical products.

Third, the advantages of automatic labeling packaging machine

1. Enhance production efficiency: automatic labeling and packaging machine with its high-speed operating capacity and continuous work mode, greatly improving production efficiency, especially for mass production needs of enterprises. The automatic operation mode of the equipment reduces the intervention of the operator, thus reducing labor costs.

2. Reduce production costs: Compared with manual labeling, fully automated labeling packaging machine can reduce the need for labor and reduce errors in the labeling process. Automated labeling process also reduces the waste of labels, so that production costs are effectively controlled.

3. Enhance product quality: automatic labeling packaging machine labeling accurate and firm, effectively improve the aesthetics of packaging and product quality. Uniform labeling effect makes the product more uniform in appearance, enhances the brand image, and improves consumer satisfaction.

4. Support for data integration and traceability: modern automatic labeling packaging machine can be integrated with the production management system (MES system) for data integration, to facilitate product traceability management. At the same time, the data in the labeling process will be automatically recorded, production managers can query the production data at any time, providing support for the intelligent management of the factory.

5. Enhance competitiveness: the intelligent design of automatic labeling packaging machine can adapt to the market demand for product diversification and high quality, to help enterprises realize the ability to quickly respond to market changes. The flexibility of the equipment enables enterprises to meet the individual needs of customers on the packaging, and enhance the competitiveness of the product market.

Fourth, the development trend of automatic labeling packaging machine

With the development of Industry 4.0 and intelligent manufacturing, automatic labeling packaging machine is moving towards intelligence, data and modularization. The future labeling equipment will use more AI technology for intelligent identification and positioning, further improving the accuracy and efficiency of labeling. In addition, the intelligent control system of the equipment will realize a higher level of automation control and data analysis, so that enterprises can control the production progress and equipment status in real time.

Conclusion Fully automatic labeling packaging machine plays an important role in modern manufacturing industry, its high efficiency, high precision, intelligent features, for enterprises in diversified and large-scale production to provide strong support. With the continuous progress of technology, the function of labeling packaging machine will be more diversified, the performance of the equipment will be continuously optimized, the future application in various industries will be more extensive. Automatic labeling packaging machine is not only packaging equipment, but also an important tool for enterprises to achieve efficient production and enhance product competitiveness.