Non-standard automation assembly machine features and application analysis

With the rapid development of the manufacturing industry and the diversification of product demand, standardized equipment can not meet all production needs. In order to solve the individual needs of specific industries and enterprises in the production process, non-standard automation assembly machine came into being. Non-standard automation assembly machine refers to the actual needs of customers, customized development of special automation assembly equipment, with a high degree of flexibility and specialization, widely used in electronics, automotive, medical equipment, home appliances and other fields. In this paper, we will discuss in depth the characteristics of non-standard automation assembly machine, the main application areas, and the advantages in the manufacturing industry.

First, the definition and characteristics of non-standard automated assembly machine

Non-standard automation assembly machine is a kind of assembly equipment tailored to the individual needs of customers, different from standardized equipment, non-standard equipment does not have uniform specifications and standards, mainly used to complete a specific process or assembly tasks. They have the following significant features:

1. Highly customized: the design and production of non-standard automation assembly machine is based on the actual needs of specific customers, the size of the equipment, operating procedures, functional modules, etc. can be flexibly configured to adapt to different production environments and product requirements. This customization makes the non-standard equipment can be well integrated into the customer's production process and improve production efficiency.

2. Strong flexibility: Due to the large differences in the production needs of different customers, the design of non-standard automated assembly machines often need to consider the future scalability and variability. Therefore, the equipment has a strong flexibility, can adapt to a variety of process adjustment or replacement of different types of production tasks, reduce the cost of equipment elimination due to changes in the production process.

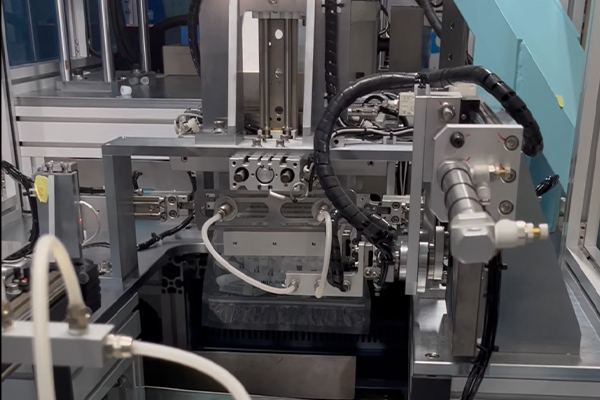

3. High precision and high efficiency: non-standard automated assembly machines are customized according to the special requirements of the product, and can realize high-precision operations, such as the assembly of precision parts and components, the detection of subtle differences. In addition, the automated workflow can effectively reduce manual operation and improve production efficiency, especially in precision assembly or multi-step production process, the effect is particularly significant.

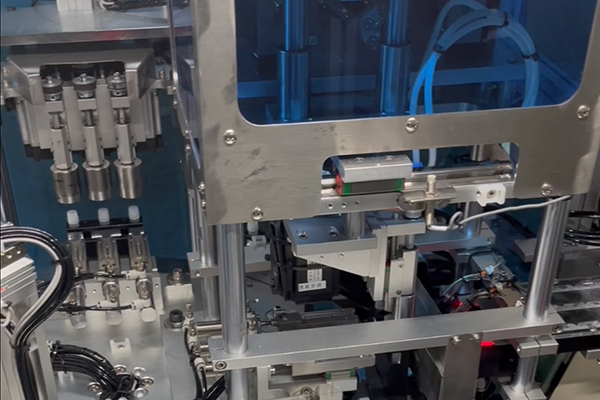

4. Intelligent control: non-standard automated assembly machines are usually combined with modern intelligent control systems, such as PLC, servo motor control, visual inspection systems, etc., to achieve precise control and intelligent operation process. Intelligent design not only improves the operability of the equipment, but also provides a technical basis for real-time monitoring and feedback of production data.

5. Complexity and long R & D cycle: the development of non-standard equipment requires a lot of technical research, program design, functional debugging, so the R & D cycle is relatively long. At the same time, the equipment needs to be combined with a number of mechanical, electrical, software and other areas of technology for comprehensive design, so there is a certain degree of complexity.

Second, the application areas of non-standard automation assembly machine

Non-standard automation assembly machine is widely used, especially in the following industries have been widely used:

1. electronics industry: the electronics industry requires high precision and speed of the equipment. Non-standard automated assembly machine can be applied to the precision assembly of electronic components, PCB circuit board placement, welding and testing of electrical components and other work. The equipment can realize the accurate positioning and assembly of tiny parts, effectively improve the product qualification rate and production efficiency.

2. Automobile manufacturing industry: automobile manufacturing involves the assembly and testing of a large number of parts, especially some small and precise parts. Non-standard automation assembly machine plays an important role in automotive parts assembly, welding, marking, testing and other aspects. For example, in the assembly process of the engine, the equipment can realize the automatic positioning and assembly of precision parts to ensure quality and consistency.

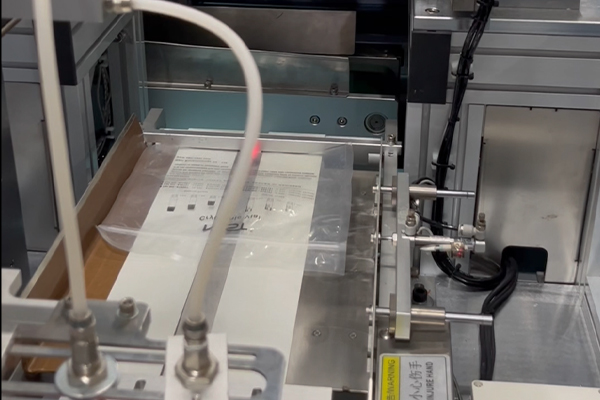

3. Medical device industry: The products in the medical device industry have extremely high requirements for precision and cleanliness. Non-standard automated assembly machines can be used for the assembly, testing and packaging of medical devices, such as syringes, medical tubes, testing instruments and other parts of the precision assembly. Non-standard equipment can not only ensure the precision of the product, but also effectively reduce human contact and reduce the risk of contamination.

4. Home appliance industry: home appliances in the production process, the need for a large number of parts and components for assembly and testing. Non-standard automated assembly machine in the production line of home appliances can complete the automatic loading of parts, assembly, functional testing and packaging of finished products and other processes, significantly improve production efficiency. For example, in the production of TV sets, washing machines and other home appliances, non-standard equipment can effectively realize the rapid assembly of multiple parts.

5. Hardware processing industry: hardware products often require the combination and connection of multiple components, non-standard automated assembly machine in the hardware processing industry can help enterprises to achieve high-precision processing and assembly, such as screws, metal frames, and other complex structures of the assembly, making the product more stable and durable.

Third, the advantages of non-standard automated assembly machine

1. Improve production efficiency: non-standard automated assembly machine to realize the automation of the process, thereby significantly increasing the production speed. In the traditional manual assembly process, the operator needs to gradually assemble the parts, and the automated assembly machine can automate these processes, so that the production efficiency is significantly improved.

2. Reduce labor costs: non-standard automation equipment can reduce the enterprise's reliance on operators, especially in areas with high labor costs are more cost-effective. The use of automation equipment reduces the need for repetitive labor, but also reduces the inconsistency of products and quality problems caused by human intervention.

3. Improve product quality: non-standard automated assembly machine through the precision control system, can ensure the accuracy of each step of the assembly, improve product consistency and quality. For products with high precision requirements, non-standard equipment can greatly reduce the quality problems caused by human error and improve customer satisfaction.

4. Shorten the production cycle: through the rapid operation of automated equipment, non-standard automated assembly machine can shorten the production cycle, especially suitable for mass production tasks. In a short time to complete the complex assembly process, to help companies respond quickly to market demand.

5. Enhance competitiveness: the flexibility and specialization of non-standard automation equipment helps enterprises to respond to the diversified needs of products and improve the adaptability and flexibility of production lines. Enterprises can quickly adjust the production program according to market changes to meet customer customization needs, thereby enhancing competitiveness.

Fourth, the development trend of non-standard automation assembly machine

With the development of science and technology, non-standard automated assembly machine gradually to the intelligent, flexible and integrated direction. In the future, the equipment will apply more artificial intelligence and Internet of Things technology to achieve intelligent optimization and automatic adjustment of the production process. At the same time, with the development of industry 4.0 and intelligent manufacturing, non-standard automated assembly machine will also be gradually integrated into the intelligent factory to realize the digital management of the whole production process.

Non-standard automation assembly machine is an indispensable and important equipment in modern manufacturing industry, and its customized features can meet the individual production needs of different enterprises, improve production efficiency, reduce costs and ensure product quality. With the development of automation technology and intelligent manufacturing, non-standard automation assembly machine will play a greater role in more industries, bringing new productivity and competitive advantage for enterprises. In the future, non-standard automation assembly machine will continue to develop in the direction of more efficient and smarter, to promote the innovation and change of the manufacturing industry.