GST fully automatic screen printing machine: a new choice to improve printing efficiency and quality

In modern manufacturing, fully automatic screen printing machines have become crucial equipment for improving printing precision and production efficiency across various industries. Whether in medical consumables, plastic products, electronic components, or packaging containers, screen printing technology is widely used for its high adhesion, wear resistance, and 3D printing effects. However, with the advancement of automation technology, traditional manual or semi-automatic printing methods are no longer able to meet the demands of mass production and high quality. This is precisely why GST's fully automatic screen printing machines stand out.

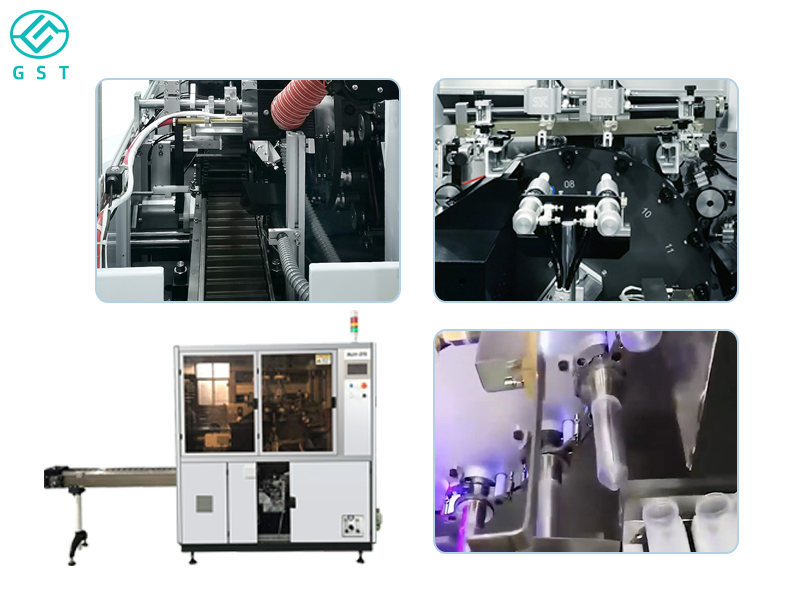

GST's fully automatic screen printing machines utilize an advanced integrated design with automated loading, positioning, screen printing, and drying systems, enabling high-speed, stable, and precise printing. The equipment's intelligent control system automates all operations, significantly reducing manual intervention, thereby lowering production costs, improving efficiency, and ensuring consistent print placement and pattern on every product.

Compared to traditional screen printing machines, GST's fully automatic screen printing machines offer significant advantages in intelligence and flexibility. Equipped with high-precision servo motors and a vision positioning system, it enables precise printing at multiple angles and on multiple curved surfaces. It is particularly suitable for screen printing on products with complex structures such as round tubes, conical surfaces, and flat surfaces, such as centrifuge tubes, pipettes, cosmetic bottles, and syringe casings. By automatically adjusting printing pressure and speed, the machine adapts to the characteristics of different materials (such as PP, PE, ABS, and glass), ensuring secure ink adhesion and clear printed images.

For production line integration, GST offers customers a complete automated screen printing solution. This fully automatic screen printer seamlessly integrates with automatic loaders, dryers, testing equipment, cartoning machines, and other equipment to create a complete automated production line, enabling unmanned operation throughout the entire process from loading to printing, testing, and packaging. This not only effectively improves production efficiency but also significantly reduces human error and defective product rates, helping companies gain a leading edge in the fiercely competitive market.

GST also prioritizes equipment stability and maintainability. The machine's structure utilizes a high-strength aluminum alloy frame and precision guide rail system, ensuring long-term operational stability. The user-friendly interface features a multi-language touchscreen interface, making commissioning, switching, and maintenance more convenient. More importantly, GST offers comprehensive technical support and after-sales service to global customers. From custom equipment design and installation and commissioning to ongoing training, our dedicated engineering team provides comprehensive support throughout the entire process, ensuring the efficient operation of each fully automatic screen printer.

In an era of high quality and efficiency, GST's fully automatic screen printers are more than just a piece of equipment; they are a core tool for businesses to achieve automation upgrades and enhance their brand value. Whether you're printing medical consumables, daily chemical packaging, electronic components, or industrial parts, GST can tailor the most suitable automatic screen printing solution based on your product characteristics and production capacity requirements. Choose GST and experience a more efficient, precise, and intelligent screen printing experience. Let GST's fully automatic screen printers help your production reach a new level of automation, digitalization, and high quality.