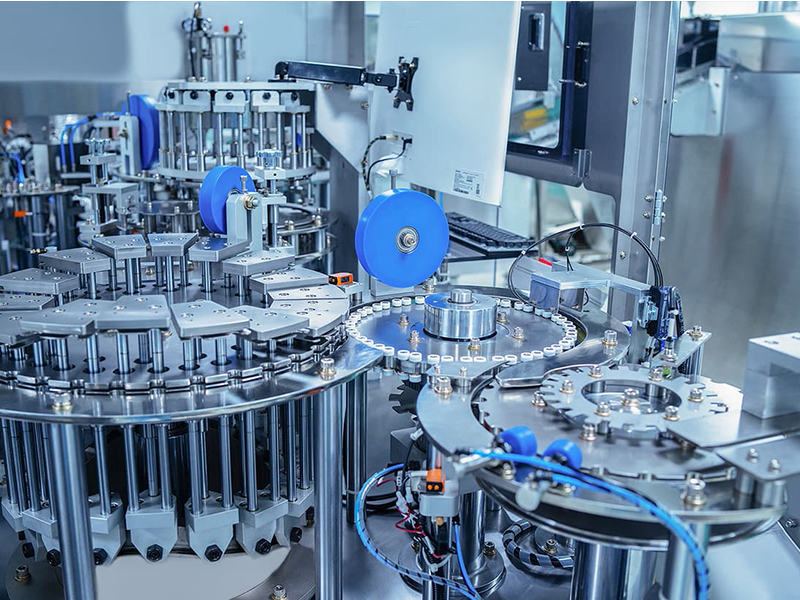

Intelligent automated production lines: Shaping the future of manufacturing

Imagine a production line where robots are busily working in an orderly fashion, each step completed autonomously without human intervention. This is the vision of future manufacturing depicted by intelligent automated production lines.

An intelligent automated production line refers to the organic integration of various stages in the manufacturing process through advanced automation and information technologies, achieving full automation and intelligence throughout the entire production process. This type of production line not only significantly improves production efficiency but also reduces production costs, bringing immense business value to enterprises.

Firstly, intelligent automated production lines offer high efficiency and reliability. Due to the application of automation technology, each stage of the production process can be completed autonomously without human supervision. This not only reduces labor costs but also avoids the impact of human factors on production, improving production quality and reliability.

Secondly, intelligent automated production lines are flexible and scalable. Through modular design, the production line can be flexibly adjusted and expanded according to the company's production needs. This allows companies to easily adapt to market changes and meet personalized production requirements.

Finally, intelligent automated production lines are sustainable. During the production process, companies can use energy monitoring and management technologies to achieve real-time monitoring and optimization of the production process, reducing energy consumption. Furthermore, intelligent automated production lines can contribute to environmental protection by reducing waste and pollutant emissions.

In conclusion, intelligent automated production lines are a crucial trend in future manufacturing. They can not only help companies improve production efficiency, reduce costs, and enhance market competitiveness, but also help them achieve sustainable development. Therefore, we should prioritize and develop intelligent automated production lines to inject more vitality and innovation into future manufacturing.