Machine Description:

1) Replace manual work to complete the automatic assembly of nut picking, placing, pressing, etc. The delivery and assembly of nuts and springs are completed at one time, which improves production efficiency;

2) Automatic detection, which can automatically detect whether the material is in place, can determine the angle of monitoring operation and the detection of abnormal status to complete one-time assembly, start with material, and stop and alarm when there is no material;

3) Adopt touch screen, intuitive interface, simple operation, and safety;

4) Output setting, automatic counting, can work continuously for 24 hours;

5) Humanized design, automatic counting;

6) Automatic shutdown alarm in case of failure, and display error message;

7) There are many after-sales service points across the country, so you can use it without worry;

8) The operator can control the action of each mechanism through the human-machine interface, and can enter and modify various working parameters, set production quantity and downtime in the interface. When the machine encounters a fault, the alarm information prompted by the interface can also be used to troubleshoot the fault.

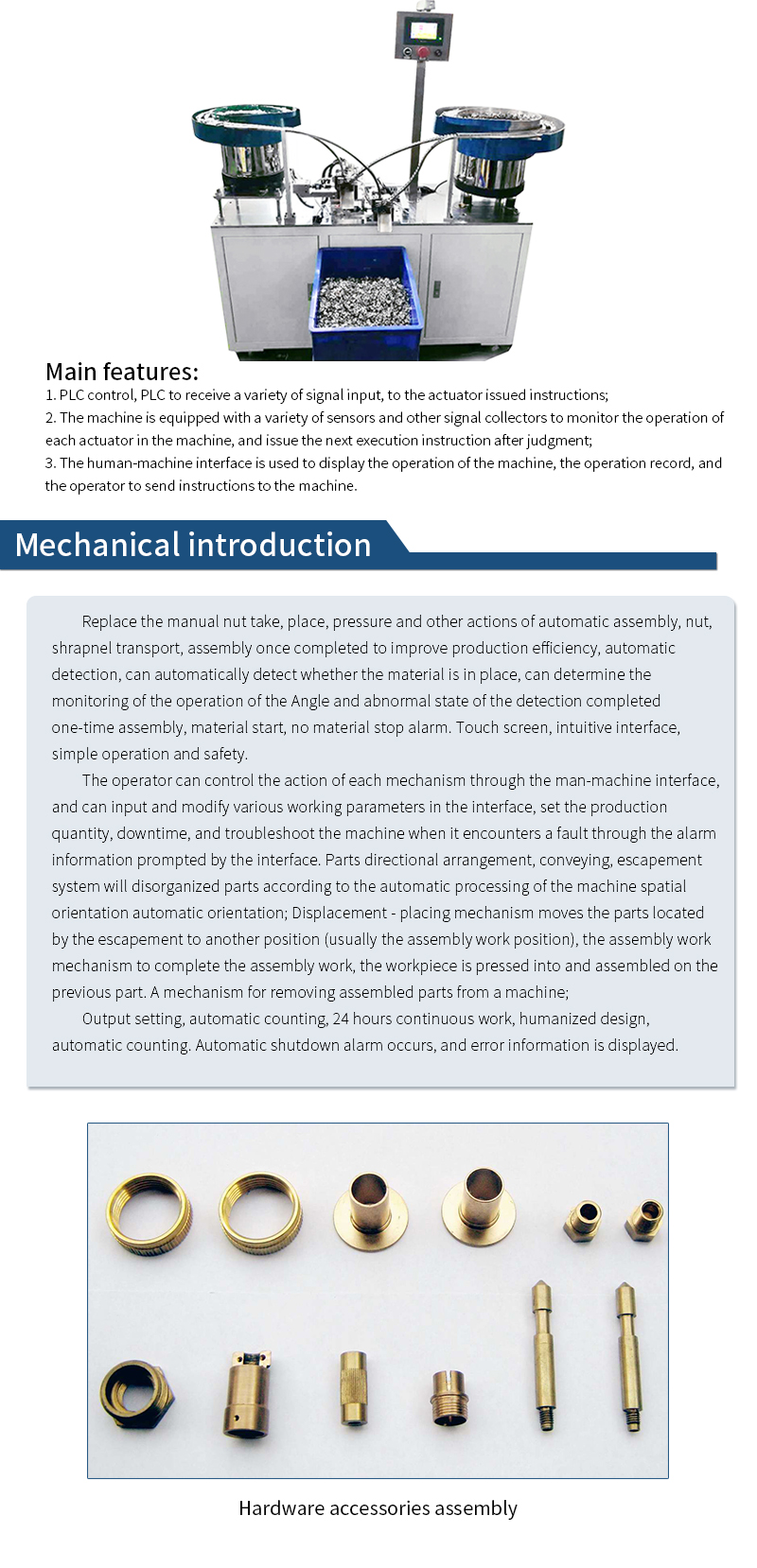

Application industry:

This type of machine is widely used in the hardware accessories assembly and processing industry.

Product advantages:

1. The directional arrangement, conveying and escapement system of parts automatically arranges the disordered parts in a spatial orientation that is convenient for the machine to automatically process;

2. The shift-placement mechanism moves the parts (components) that are fixed by the escapement mechanism to another position (usually the assembly work position);

3. The assembly work mechanism is a mechanism to complete the main action of the assembly work, pressing the workpiece into and assembling it on the previous part;

4. The workpiece removal mechanism is a mechanism used to remove the assembled parts from the machine;

5. PLC control is adopted. PLC needs to receive various signal inputs and issue instructions to each actuator. The machine is equipped with a variety of sensors and other signal collectors to monitor the operation of each actuator in the machine, and issue the next execution instruction after judgment. The human-machine interface is used to display the operation status and operation records of the machine, and is used for the operator to issue instructions to the machine.

Copyright © GuanShenTai Automation