The Automatic Paste Weighing Filling Machine is an intelligent filling device designed specifically for high-viscosity paste materials (such as creams, emulsions, gels, and sauces). It is widely used in the cosmetics, daily chemical, food, and pharmaceutical industries. It utilizes an advanced weighing feedback control system, achieving high-precision quantitative control during the filling process, effectively improving production efficiency and product consistency.

High-precision weighing control: The machine is equipped with a high-precision electronic weighing module, which monitors material weight in real time during the filling process, ensuring accurate and consistent fill quantities every time. By integrating weighing feedback with the filling head control, errors such as missed, underfilled, and overfilled filling are significantly reduced.

Adaptable to the characteristics of paste materials: For high-viscosity materials (such as creams, ointment dressings, and gels), the machine utilizes either a screw pump or a plunger pump, supporting a "fast-first, slow-last" filling strategy to minimize air bubbles, stringing, and overflow.

Automated operation: The machine supports automatic metering, filling, weighing, and rejection functions, reducing manual intervention, improving production efficiency, and minimizing human error.

Modular design for easy cleaning and maintenance: Material-contacting parts are made of stainless steel (such as 304/316L) and suitable seal materials. The modular design of the equipment structure allows for easy disassembly and cleaning, fast mold changes, and complies with GMP and clean production requirements.

Intelligent control system: Equipped with a PLC control and touch screen interface, it allows for presetting different product formulas, filling volumes, speeds, and weighing error alarm thresholds. It also features automatic calibration, statistical recording, and fault alarm functions, facilitating production management and quality traceability.

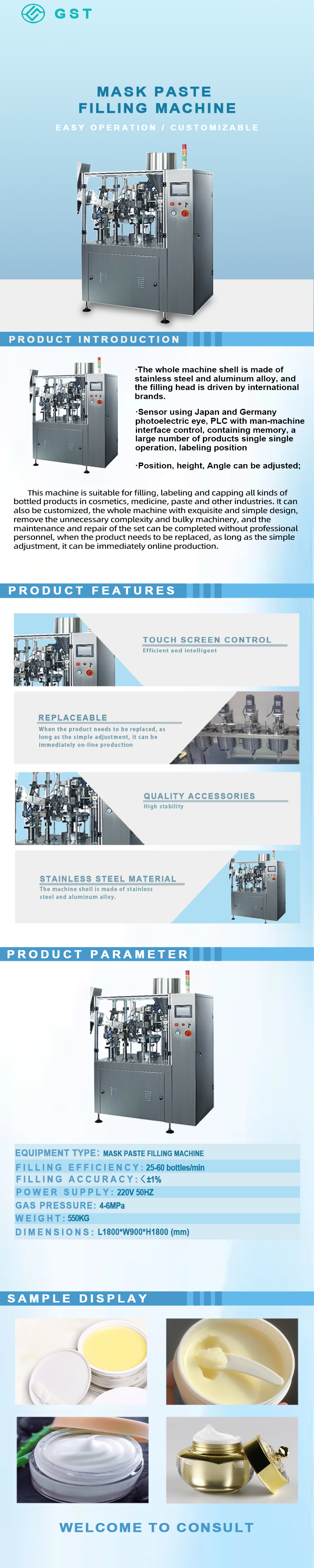

Technical parameters:

Model Number: GST-SWYP007A

Filling efficiency: 25-60 bottles/minute;

Filling accuracy: <±1%;

Power supply: 220V 50HZ;

Air pressure: 4-6MPa;

Dimensions: 1800*900*1800mm;

Mass: 550KG.

Customized Support: Yes

Copyright © GuanShenTai Automation