Automated pharmaceutical visual inspection machines are crucial in the manufacturing of pharmaceuticals and in vitro diagnostic (IVD) devices, addressing product quality risks such as cosmetic defects, visible foreign matter, insufficient liquid levels, and poor seals. Specifically designed for disposable consumables such as vials, ampoules, small-volume injections, lyophilized powder injections, and sample tubes, these machines deliver efficient, stable, and accurate automated visual inspection, ensuring quality assurance for production lines.

High-speed visual inspection system: Equipped with a high-resolution industrial camera and intelligent image processing algorithms, the equipment can identify defects such as glass shards, metal fragments, fibers, white spots, impurities, low liquid levels, and cracks within pharmaceutical bottles or ampoules in real time. Traditional manual visual inspection is prone to fatigue and missed detections, while automated systems can operate continuously 24 hours a day and provide consistent inspection results.

Automated bottle rotation + light source illumination: Once a vial enters the inspection area, it rotates at high speed on a turntable or rotating mechanism, causing the liquid inside the vial to move relative to the bottle. The visual inspection system captures the potential particle motion during this cycle, improving detection sensitivity.

Rejection Mechanism: After the system automatically identifies defective products, it removes them using air blowing, robotic arms, or slides, preventing them from entering the subsequent packaging process. This reduces manual inspection and minimizes the risk of missed inspections.

Intelligent Control Interface: Equipped with a PLC and touchscreen human-machine interface, parameters such as inspection speed, lighting intensity, rejection strategy, and alarm thresholds can be configured. The device also records inspection data, rejection statistics, and images for archiving, facilitating quality traceability.

Modular Design: The machine structure meets the requirements of pharmaceutical cleanrooms, with key components constructed of stainless steel and dust-proof covers for easy maintenance and cleaning. Molds and fixtures support quick changeovers to accommodate different sizes and bottle shapes.

High Adaptability: The machine can inspect a variety of packaging formats, including glass bottles, plastic bottles, ampoules, small needles, and sample tubes, making it suitable for industries such as pharmaceuticals, in vitro diagnostics, vaccines, and biologics.

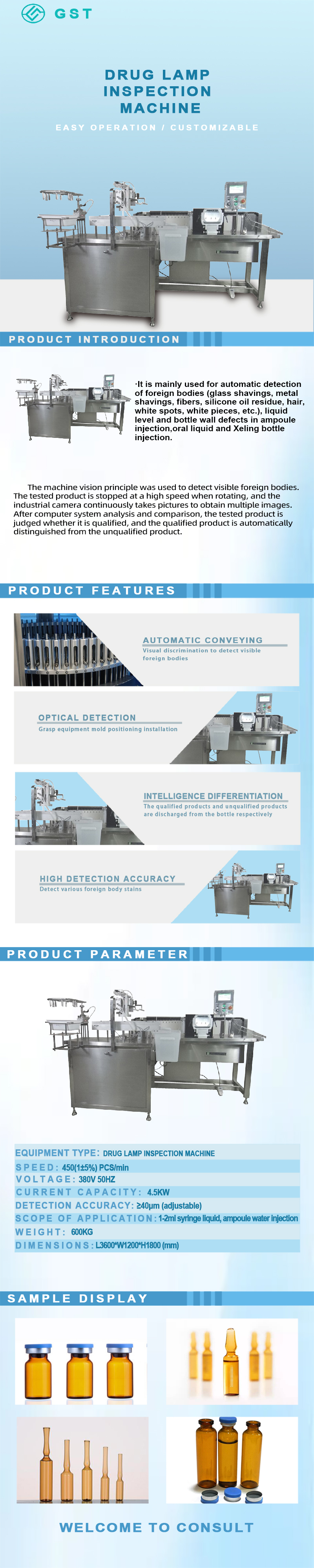

Technical Parameters:

Model Number: GST-SWYP001A

Applicable Scope: 1-2ml syringe liquid, ampoule injection;

Inspection Items: Visible foreign matter (glass shavings, metal shavings, silicone oil residue, fibers, white spots, white blocks), liquid level;

Inspection Speed: 450 (1±5%) pieces/minute;

Inspection Accuracy: ≥40 μm (adjustable);

Capacitance: 4.5 kW;

Voltage: AC 380 V, 50 Hz;

Workbench Height: 900 mm;

Overall Dimensions: 3600 x 1200 x 1800 mm;

Weight: 600 kg

Customized Support: Yes

Copyright © GuanShenTai Automation