The semi-automatic paste filling machine is an intelligent filling device designed specifically for high-viscosity materials such as pastes, gels, and creams. It is widely used in the cosmetics, daily chemical, pharmaceutical, and food industries. Designed for quantitative filling, stability, and ease of operation, this machine meets the needs of small- to medium-volume production of color-coded, tube-, and bottled paste products. It is an essential option for companies upgrading from manual or simple mechanical filling to automation.

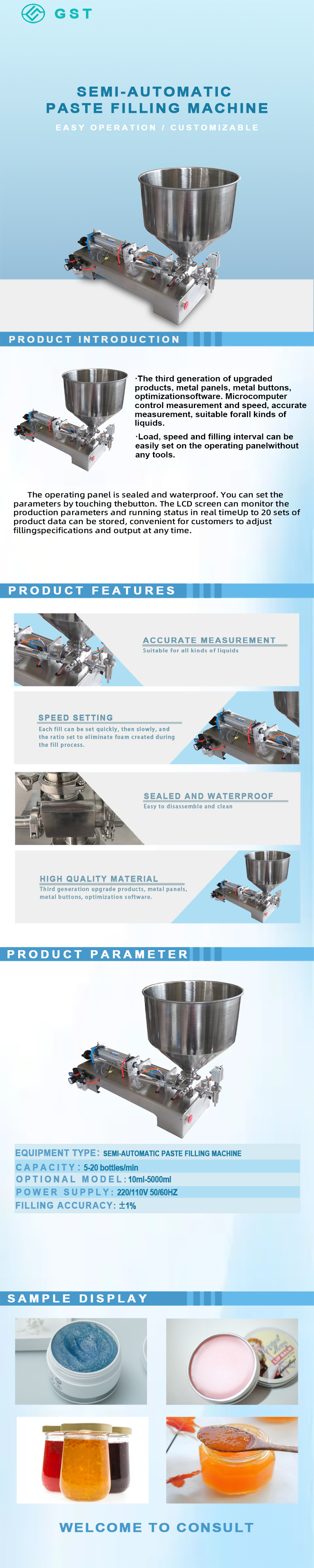

Quantitative Filling Control: The machine utilizes a piston or screw filling system, combined with precise pneumatic/servo control, to ensure accurate and consistent filling quantities every time, eliminating material waste and errors. Industry data indicates that this type of equipment achieves a filling accuracy of ±1%.

Semi-automatic Operation: The machine utilizes manual bottle placement/container placement, automatic push-filling, and manual bottle removal. Its simple design and convenient operation make it suitable for small and medium-sized production operations. It significantly improves filling efficiency without the need for a full automation line.

Suitable for high-viscosity paste materials: For paste-like materials (such as creams, gels, and cream dressings), the equipment is equipped with an anti-drawing nozzle and an anti-drip device. The filling head can be raised and lowered to reduce foaming and backflow, ensuring precise placement of materials into bottles.

Clean Structure and Easy Maintenance: The equipment's material-contacting parts are made of stainless steel (e.g., 304/316), meeting cleanroom production requirements. Its compact, modular design allows for easy disassembly and cleaning, making it suitable for use in cleanrooms.

Multiple Specification Compatibility and Quick Changeover: The equipment supports filling bottles, cans, and tubes of varying sizes by simply replacing the filling head or adjusting the lifting mechanism, quickly responding to diverse, small-batch production needs.

Safe and Stable Operation: The equipment is equipped with a protective cover, leak detection, air pressure monitoring, and fault alarm systems to ensure safe operation and stable production.

Technical parameters:

Model Number: GST-SWYP003A

Sizes: 1600*300*1000mm

Optional models: 10ml -5000ml ;

Power supply: 220/110V 50/60HZ.

Air pressure: 0.4-0.6MPa.

Filling speed: 5-20 bottles/minute (the machine power for the gas source, can meet the large and small enterprises to use);.

Filling precision: ≤±1%.

Customized Support: Yes

Copyright © GuanShenTai Automation