The 96-well plate automatic filling, sealing, and labeling machine is a fully automated production system designed specifically for the high-throughput laboratory consumables and IVD (in vitro diagnostic) industries. This system integrates automatic plate loading, quantitative filling, heat or film sealing, labeling, visual inspection, and rejection, significantly improving production efficiency and product consistency. It is suitable for batch filling and packaging of multiple sample or reagent plates, including 96-well and 384-well plates.

Automatic plate loading and precise positioning: The machine automatically loads 96-well plates from a rack or conveyor system and uses a precise positioning mechanism to deliver each well to the filling station, ensuring a fast process and accurate positioning.

High-precision filling system: Utilizing a multi-channel filling head (optional ceramic pumps, peristaltic pumps, or valve-controlled pumps), each channel independently controls the filling volume and speed, adapting to varying liquid viscosities and enabling fine-tuning for each well to minimize errors.

Sealing/Film Sealing: After filling, the plate automatically moves to the sealing or film sealing station, where it is sealed using heat or film pressing. A variety of sealing methods are compatible, ensuring a secure seal for sample or reagent solutions.

Labeling and Traceability: After sealing, the system automatically affixes a batch number barcode or QR code label for product traceability. Accurate label placement ensures downstream logistics and information traceability.

Inline Inspection and Rejection: Equipped with visual recognition or photoelectric inspection systems, key quality indicators such as fill volume, film sealing integrity, and label placement are monitored in real time. Unqualified deep-well plates are automatically rejected, improving yield.

Flexible Format Switching: The system's design supports interchangeable fixtures and parameter settings, making it compatible with various deep-well plate formats, such as 96-well and 384-well, making it suitable for diverse production environments.

Significantly Increase Production Capacity: Compared to manual operations, automated, integrated processes significantly increase production cycle times.

Improve Quality Consistency: Precision filling and in-line testing reduce human error and ensure product standardization.

Reduce Labor and Operating Costs: Process automation reduces manual intervention, lowers labor costs, and improves operational safety.

Enable Information Management: Labeling and traceability capabilities facilitate the establishment of a digital production management system.

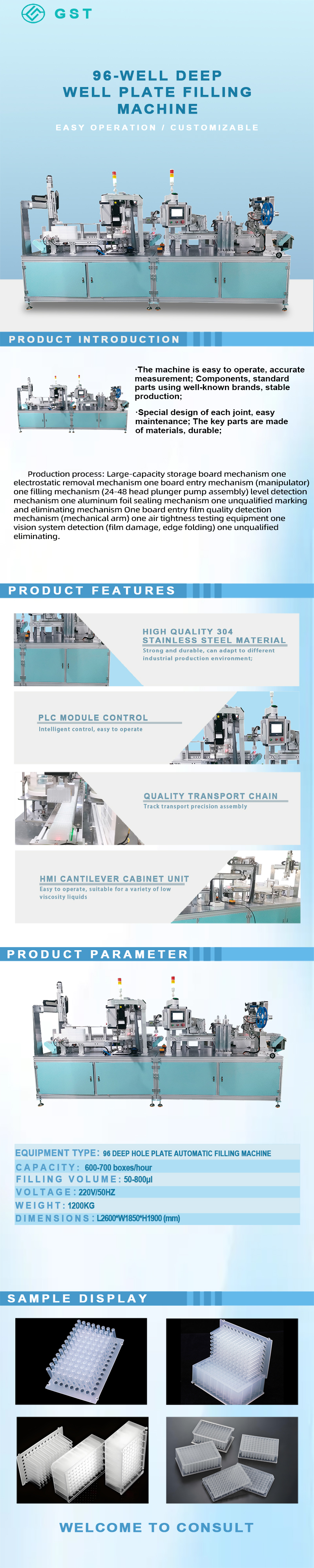

Equipment Details:

Model Number: GST-SWYP004A

Sizes: L4200*W1200*H1800 (mm)

Production Capacities: 600-700 boxes/hour

Filling volume:50-800uL

Total power:5KW

Power supply voltage:220V/50HZ

Weight:1200KG

Customized Support: Yes

Copyright © GuanShenTai Automation