The automatic liquid dosing filling machine is a fully automated device integrating intelligent control, high-precision metering, and high-speed filling. It is designed specifically for the filling needs of liquid products in the pharmaceutical, biological product, daily chemical, food, and chemical industries. It automates the entire process, from automatic loading, precise dosing, drip-free control, to automatic bottle discharge. It is widely used in high-cleanliness production lines for liquid products such as reagents, disinfectants, essential oils, oral liquids, lotions, and perfumes.

I. Equipment Overview

This equipment utilizes a servo motor-driven metering pump or flowmeter control system, combined with high-sensitivity sensors and precision pneumatic actuators to ensure accurate and consistent filling of every bottle. The entire line can be equipped with an automatic bottle unscrambler, capping machine, labeler, and inspection and rejection system to meet production requirements, enabling unmanned continuous production and significantly improving production efficiency and product quality.

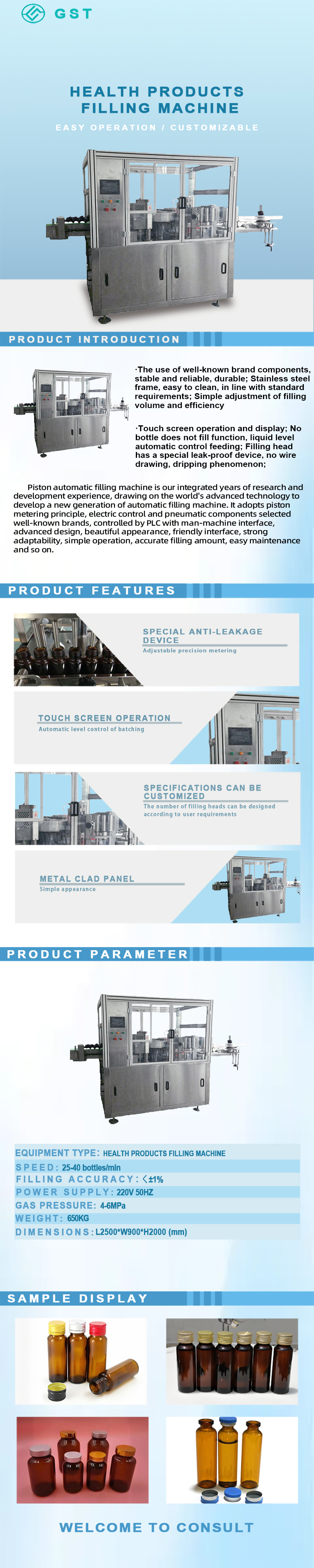

II. Core Functions and Technical Highlights

High-precision dosing system: Utilizing imported flowmeters or servo plunger pumps, the system ensures a filling accuracy error of less than ±0.5% for each bottle, meeting the high-standard production requirements of pharmaceuticals and reagents.

Intelligent Filling Control: Automatically adjusts filling speed and back-sucking force based on liquid characteristics (such as viscosity, foaming, and corrosiveness) to prevent splashing and dripping.

Multi-channel Synchronous Filling: Supports simultaneous operation of 2 to 12 units, with freely configurable production capacity to meet different batch production needs.

No-Bottle, No-Fill Protection: Photoelectric detection prevents misfilling, missed filling, and waste, ensuring production safety and conserving raw materials.

Intelligent Human-Machine Interface: The PLC programmable control system, combined with a touchscreen interface, enables intuitive parameter settings, automatic counting, production data statistics, and abnormality alarms, ensuring easy operation.

Compatible with Various Bottle Shapes: The filling platform allows for quick mold changes to accommodate bottles of varying sizes and shapes, enabling flexible production.

III. Performance Advantages

High-Efficiency Production: Integrated automatic bottle loading, quantitative filling, and unloading significantly reduces labor costs and improves production cycle time.

High Filling Accuracy: Utilizing a precision servo control system, the filling process is stable and the flow rate is adjustable.

Clean and Safe Design: Constructed entirely of 304/316 stainless steel, the machine complies with GMP and FDA production standards, is easy to clean, and corrosion-resistant.

Integration Support: Can be combined with a capping machine, labeling machine, cartoning machine, and inspection machine to form a complete automatic filling production line, achieving full automation.

Easy Maintenance: The modular design allows for quick assembly and disassembly, facilitating cleaning and maintenance.

Technical parameters:

Model Number: GST-SWYP005A

Filling capacity: 25-250ml,50-500ml,150-1000ml,500-2500ml(different specifications can be ordered).

Canning efficiency: 25-40 bottles/minute (6 heads in the range of 50-500ml).

Canning precision: <±1%.

Power supply: 220V 50HZ.

Air pressure: 4-6MPa.

Overall dimension: 2500*900*2000mm.

Quality: 650KG.

Customized Support: Yes

Copyright © GuanShenTai Automation