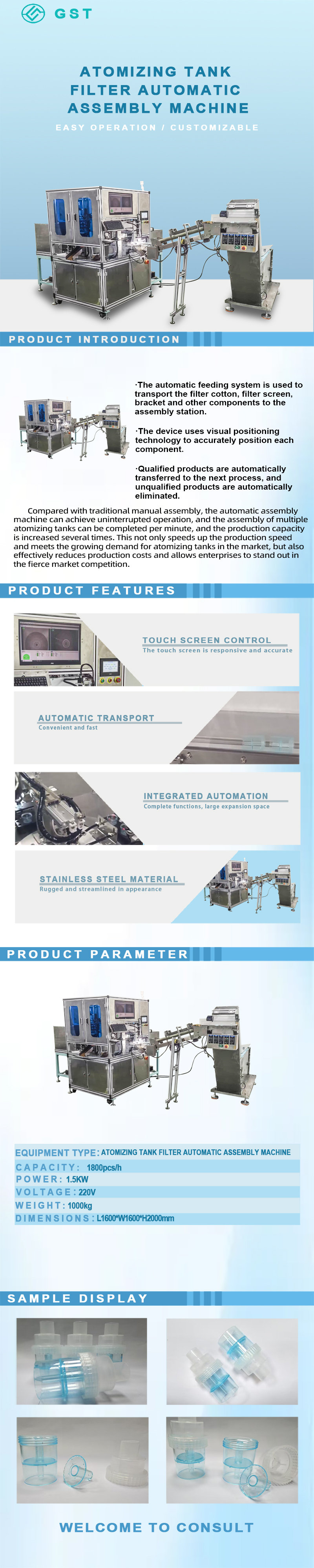

The automatic assembly machine for atomizer can filters is a high-end automated assembly device designed specifically for the nebulizer consumables industry. It automates the entire process of atomizer can filter components (e.g., filter element, filter screen, and housing), from loading, positioning, assembly, pressing, testing, to discharge. It is suitable for the production of medical respiratory devices, nebulizers, and related filter products.

Automatic Loading and Positioning: Equipped with a vibrating plate/conveyor belt automatic loading system, it precisely delivers filter elements, filter screens, housings, and other components to the assembly station.

High-Precision Assembly and Pressing: Utilizing a servo drive and precision mechanical structure, it integrates filter element insertion, filter screen pressing, and housing assembly, ensuring stable and consistent assembly.

Integrated Testing Module: A built-in inspection station tests assembled filters for sealing and airflow, ensuring each product meets performance standards.

Modular Design and Quick Changeover: The modular structure allows for quick interchange of fixtures and molds, adapting to the production of filters of varying specifications and significantly improving flexible production capabilities.

Intelligent PLC Control and Human-Machine Interface: A touchscreen interface allows for flexible parameter settings, built-in alarm systems, statistical functions, and remote monitoring capabilities. System operating data can be traced and analyzed.

Cleanroom Compatibility: The unit utilizes stainless steel and a dust-proof design, ensuring extremely high cleanliness requirements for filter components, meeting the production standards of the respiratory device industry.

Equipment Details:

Model Number: GST-WHG001A

Sizes: L160cm*W160cm*H200cm

Weight: 1000kg

Power: 1.5KW

Production Capacity: 1800 PCS/hour

Voltage: 220V/50Hz

Core Components: Motor, CCD System

Customized Support: Yes

Copyright © GuanShenTai Automation