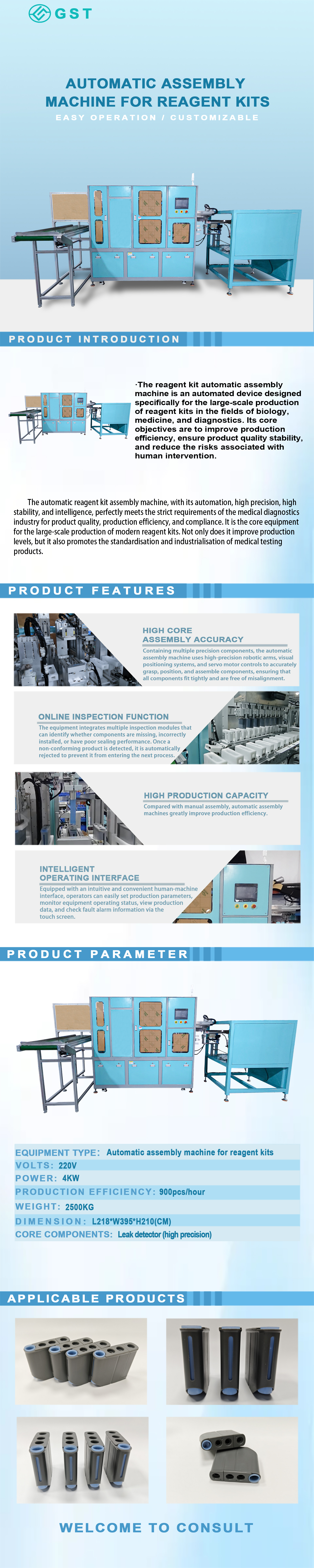

The automated test kit assembly and testing machine is a highly efficient, automated device designed specifically for the production of in vitro diagnostic (IVD) test kits. It integrates component loading, precision assembly, seal testing, liquid/air leak detection, and rejection and sorting. With an intelligent control system at its core, the machine automates the entire test kit assembly and testing process, from material loading to qualified shipment, significantly improving production efficiency and product quality consistency.

Core Functions and Structural Features

Automated Assembly Process: The machine automatically loads, positions, assembles, and assembles test kit components, including the test kit housing, core, reagent strip, and cover, replacing traditional manual assembly methods and improving assembly speed and accuracy.

Seal and Leak Detection: An integrated high-precision airtightness/liquid-tightness testing module performs real-time testing on each assembled test kit, quickly identifying defects such as inadequate seals, air leaks, and cracks, ensuring assembly quality and product safety.

Intelligent Control System: Utilizing a PLC and touchscreen interface, the machine supports pre-set multiple test kit specifications, automatically adjusts parameters, and supports rapid changeovers, data storage, and production statistics. The machine also features abnormality alarms, automatic rejection of defective products, and cleaning reminders.

Modular Design and High Compatibility: The entire system utilizes a modular structure, allowing for quick replacement of fixtures, molds, and feeding systems to accommodate test kits of varying sizes and specifications, adapting to the production needs of diverse varieties, small batches, and multiple specifications.

Cleanroom Compatibility: Product-contact components are constructed from materials consistent with medical/laboratory consumable standards. The compact design, easy-to-clean, and low-dust design meet the stringent cleanroom requirements of IVD production.

Equipment Details:

Model Number: GST-SJH001A

Sizes: L396cm*W218cm*H210cm

Weight: 2500kg

Power: 4kW

Production Capacity: 900 units/hour

Voltage: 220V

Core Component: High-precision leak detector

Customized Support: Yes

Copyright © GuanShenTai Automation