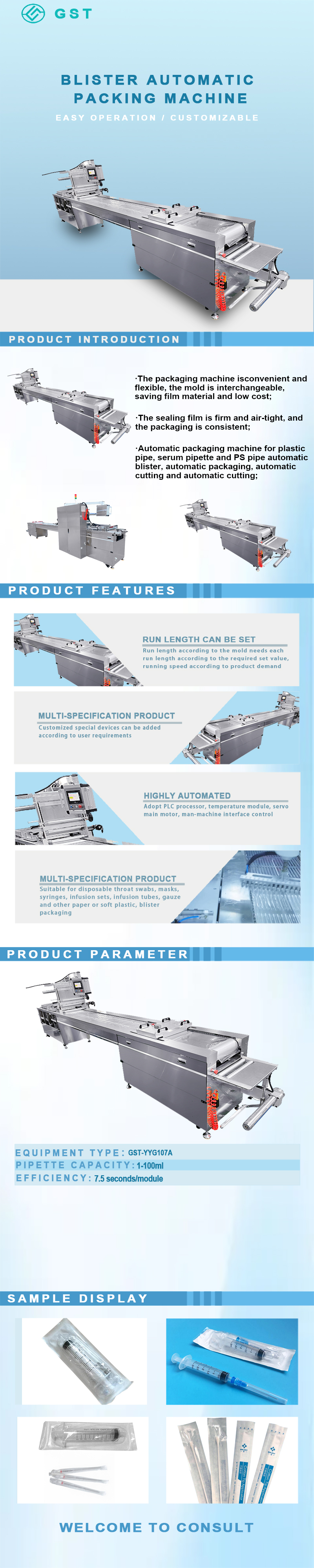

The automatic blister packaging machine is a highly efficient, fully automated blister forming and packaging system designed specifically for industries such as medical devices, laboratory consumables, and electronics. It integrates blister forming, loading, sealing, cutting, and discharging functions, enabling continuous, automated operations from raw film rolls entering the machine to finished packaged products exiting the machine, effectively improving production efficiency and ensuring consistent packaging quality.

Core Functions and Technical Highlights:

Integrated blister forming and sealing: The machine combines film softening through heating, mold forming, component placement, film sealing, hot pressing, and cutting, streamlining the process and improving cycle time.

Quick Mold Changeover: The modular design allows for quick replacement of blister forming and sealing molds of varying sizes, adapting to the packaging needs of a wide range of products, such as pipette tips, sample tubes, plastic rods, and electronic components.

Energy-saving and low-film-consumption design: The machine utilizes optimized forming and sealing processes to reduce film roll waste and sealing energy consumption, helping customers lower packaging consumables and energy costs.

Highly clean design, suitable for cleanroom environments: The equipment utilizes a stainless steel frame and dust cover, resulting in a compact, easy-to-clean motion path that meets the cleanliness standards for medical and laboratory consumable packaging.

Strong line integration: It seamlessly integrates with upstream equipment such as feeding, testing, labeling, and cartoning to form a complete automated packaging production line, meeting medium- to large-scale production capacity requirements.

Technical parameters:

Equipment Model: GST-YYG107A

Pipette capacity: 1-100ml

Sizes: L6000*W900*H1800mm

Production Capacities: 7.5 seconds/module

Power (Output): 380VAC

Customized Support: Yes

Copyright © GuanShenTai Automation