The automatic ultrasonic pipette welding machine is a highly efficient, automated device designed specifically for the production of laboratory consumables. It is primarily used for glue-free, high-strength welding of plastic tubing, such as pipettes, sample tubes, and plastic tips. It integrates automatic feeding, precise positioning, ultrasonic welding, and outfeed inspection, meeting the stringent cleanliness and sealing requirements of medical consumables.

Ultrasonic Welding Principle: The machine uses an ultrasonic generator to convert electrical energy into high-frequency vibration energy (20 kHz–40 kHz), which is then transmitted to the welding head. This results in instantaneous melting and solidification of the plastic tubing, ensuring clean, pollution-free welding without the use of glue or auxiliary materials.

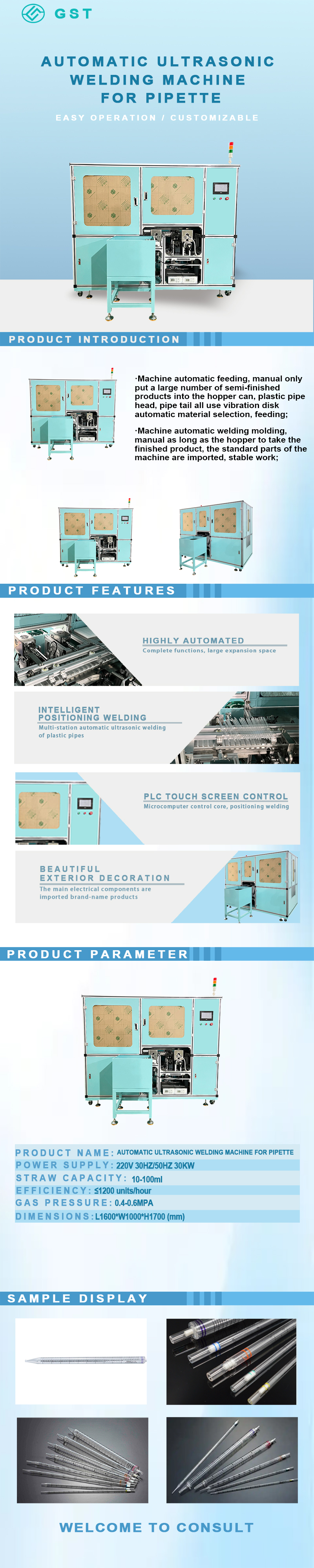

Automatic Feeding and Positioning: A vibrating plate or feeding device automatically arranges and transports the tubing to the welding station, ensuring precise positioning. An automatic material selection system at the head and tail allows for rapid switching between production specifications.

Efficient Forming and Welding: The machine utilizes imported brand standard components. The welding head, coupled with a precise pressure control system, can complete welding cycles in a short time, effectively increasing production capacity.

Modular Design and Flexible Mold Changeover: The modular structure of the equipment supports the production of pipettes of varying sizes (e.g., 10-100 mL). Customers can quickly adjust molds and parameters based on production capacity and size changes.

Clean, Environmentally Friendly, and Highly Reliable: Glue-free welding eliminates chemical residues and releases no hazardous substances during operation, meeting clean manufacturing requirements for medical consumables.

Technical Parameters:

Equipment Model: GST-YYG103A

Pipette capacity: 10-100ml (1 set of equipment can only process a capacity of the pipette)

Ultrasonic equipment: Taiwan brand Evergreen 15-20K

Sizes: L2500xW1500xH1200 (mm)

Production Capacities: 1100-1200 pcs/hour

Power (Output): 4.3KW

Customized Support: Yes

Copyright © GuanShenTai Automation