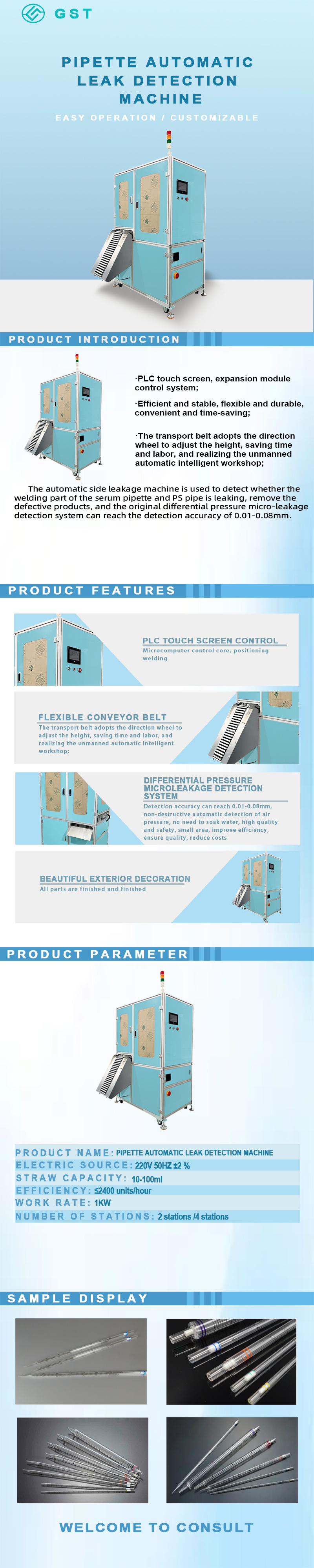

The automatic pipette leak detector is a high-precision inspection device designed specifically for laboratory consumables manufacturers. It is primarily used for automated airtightness testing of disposable pipettes. The device integrates automatic loading, positioning, seal testing, and rejection, enabling an efficient, stable, and fully automated inspection process, helping production lines improve product consistency and quality reliability.

Core Functions and Structural Features:

High-precision inspection system: The device utilizes advanced sensors and differential pressure/vacuum detection technology to quickly identify defects such as poor pipette seals, leaks, cracks, and weld defects.

Automated Process: The entire process, from pipette loading, positioning, leak detection, rejection, to discharge, is controlled by a PLC and touch screen, minimizing manual intervention and achieving high inspection efficiency, making it suitable for assembly line production.

Modularity and High Compatibility: The modular design supports switching between pipettes of different sizes, capacities, and materials, allowing for fast mold changes and adapting to the needs of high-variety, small-batch, and multi-specification production.

Clean Design: The device's contact areas with the pipette are constructed of clean materials consistent with medical/laboratory consumables. The compact design and ease of cleaning and maintenance meet the cleanliness requirements of laboratory consumables production.

Intelligent Alarm and Data Traceability: The system automatically generates alarms when abnormalities are detected, rejects defective products, and records test data, facilitating quality management and traceability, enhancing product reliability.

Technical Parameters:

Model: GST-YYG104A

Pipette capacity: 10-100ml

Sizes: 1700*1500*1850mm

Production Capacities: 2000-2400pcs/h

Power (Output): 1KW

Customized Support: Yes

Copyright © GuanShenTai Automation