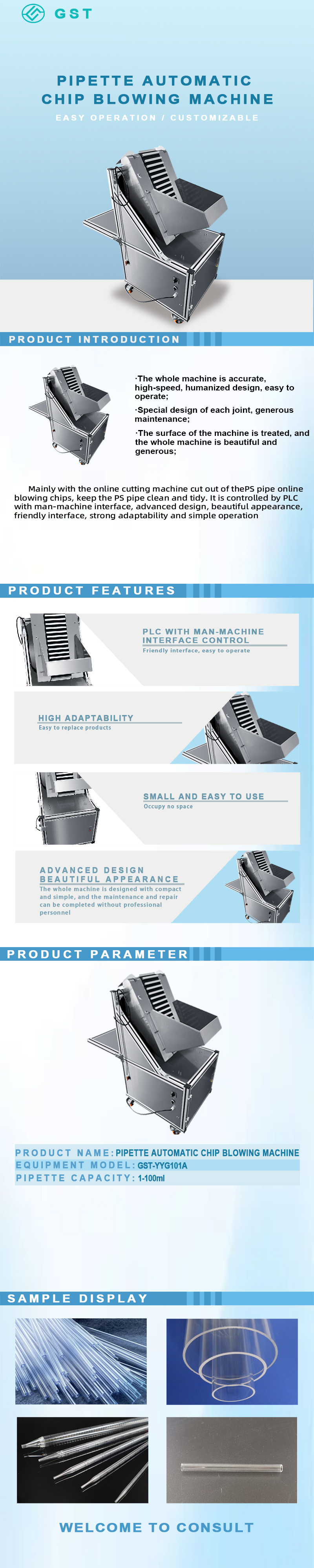

The automatic pipette chip blower is an automated cleaning module designed specifically for laboratory consumables production lines. It is primarily used for cleaning and removing chips from plastic pipettes, tips, and other pipettes before and after cutting, grinding, and printing.

Using high-speed airflow or compressed gas purging technology, the device effectively removes residual debris, powder, burrs, and tiny plastic particles from inside and outside the pipette, ensuring cleanliness and stability during downstream printing, assembly, and sealing processes.

High-speed chip blowing: The device utilizes dedicated air jets and vacuum suction channels to simultaneously clean both the inner cavity and outer wall of the pipette, effectively reducing debris accumulation and lowering the risk of subsequent process failures.

Intelligent control system: Equipped with a PLC controller and touchscreen interface, the loading, blowing, and unloading processes are automated. Parameters such as cycle time, airflow intensity, and cleaning frequency can be customized to accommodate pipette sizes.

Modular design: The stainless steel frame and removable purge chamber facilitate maintenance and cleaning. The compact design allows for easy integration into pipette production lines before cutting, printing, and filling.

Compatible with Multiple Tubing Specifications: Supports pipettes and related plastic tubing in multiple sizes, including 0.1 mL, 10 mL, and 200 μL, with fast switching and flexible support for small-batch and high-variety production.

Cleanroom Compatibility: All tubing-contacting components are made of food-grade/medical-grade materials. The dust cover and airflow separation design meet cleanroom requirements, helping to reduce particulate contamination of products.

Efficiency Improvement: Compared to manual chip cleaning and blowing, automated chip blowing is faster, more stable, and synchronized with production lines.

Quality Assurance: Clean chip blowing reduces particulate residue, improves printing and sealing quality, and reduces rework.

Flexible Modification: Accommodates multiple specifications and fast switchover, making it suitable for companies producing diverse products.

Technical parameters:

Equipment Model: GST-YYG101A

Pipette capacity: 1-100ml

Sizes: 1500*1000*1500mm

Production Capacities: 300pcs/min

Power (Output): 1.5kw

Customized Support: Yes

Copyright © GuanShenTai Automation