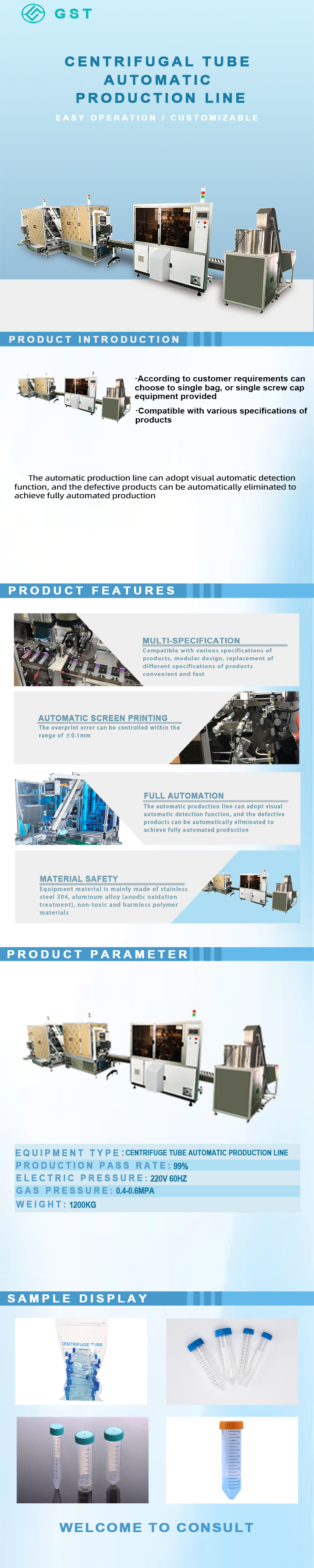

The centrifuge tube automatic production line is a highly efficient automated equipment designed specifically for the laboratory consumables industry. It is primarily used for the fully automated production of various disposable laboratory consumables, including centrifuge tubes, cryopreservation tubes, and sampling tubes.

The equipment integrates automatic loading, screen printing, capping, counting, bagging, coding, labeling, and testing functions, enabling unmanned operation throughout the entire process, significantly improving production efficiency and product consistency.

The line utilizes a high-precision servo drive system, combined with PLC intelligent control and a touchscreen interface, to precisely control and ensure high-quality processing of each centrifuge tube.

The entire machine is constructed of stainless steel and features a modular design, complying with GMP production standards, facilitating cleaning, maintenance, and switching between multiple product sizes.

The centrifuge tube automatic production line supports the automated production of a variety of tube types and can be integrated with subsequent equipment such as automatic loading, screen printing, capping, counting, bagging, coding, labeling, and testing to form a complete automated production line.

This centrifuge tube automatic production line is widely used in the IVD, pharmaceutical, life science, and biopharmaceutical industries, helping companies achieve digital production, increase production capacity, and significantly reduce labor costs and operational risks. The equipment has a built-in error-proofing alarm system that can automatically reject pipes with production anomalies or damage, ensuring that the qualified rate of finished products reaches more than 99%.

Technical parameters:

Equipment Model: GST-LXG100A

Centrifuge tube capacity: 15-50ml

Sizes: L8800*W1800*H1800mm

Production Capacities: 500pcs/min

Power (Output): 3KW

Customized Support: Yes

Copyright © GuanShenTai Automation