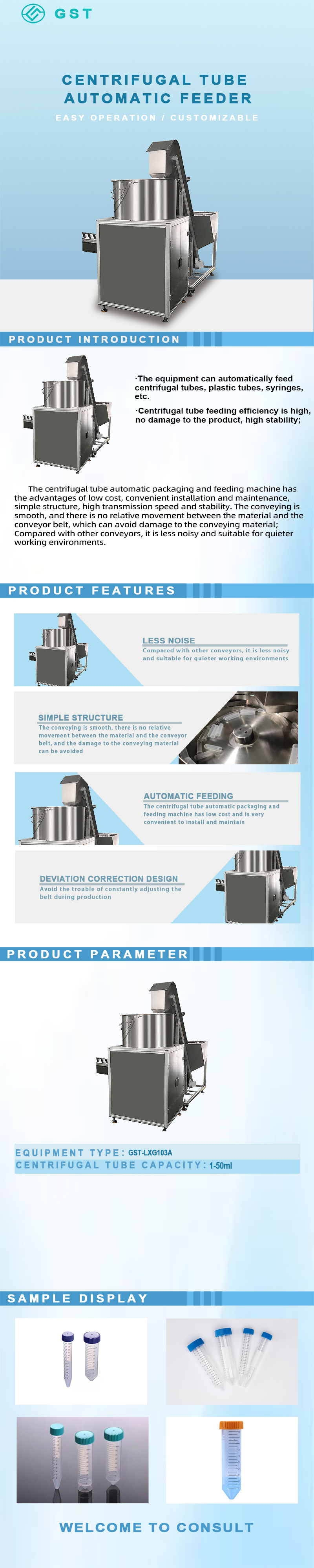

The Centrifuge Tube Automatic Loader is designed specifically for automated loading processes in the manufacturing of laboratory consumables such as centrifuge tubes and plastic sample tubes. It aims to replace traditional manual loading methods, achieving high-speed, stable, and damage-free tube conveying and alignment, thereby improving production efficiency, reducing labor costs, and enhancing quality consistency.

Core Functions and Structural Highlights:

Automatic Feeding and Alignment: The device utilizes a vibrating plate, spiral feeder, or vacuum suction to continuously and stably transport centrifuge tubes from a silo or hopper to subsequent processing steps. It supports rapid switching between multiple specifications of centrifuge tubes, making it ideal for customers with diverse production lines and frequent specification changes.

Improved Efficiency and Cost Reduction: Compared to manual loading, this device delivers continuous, high-speed feeding, reducing manual intervention and improving production line cycle time.

Non-Loss Conveyor Design: The conveyor channel, vibrating plate, and alignment track are optimized to prevent centrifuge tubes from tipping, breakage, or jamming during feeding and alignment.

Stable and Reliable Structure: The main structure is constructed of stainless steel and aluminum alloy, with protective covers installed at key locations. It operates quietly and is easy to clean and maintain. Manual contact is eliminated during the feeding process, effectively reducing breakage and the risk of foreign matter contamination, meeting clean manufacturing requirements.

Modular Drive Control: Equipped with a PLC control system and touchscreen interface, parameters such as feeding frequency, vibration intensity, and conveying speed can be flexibly adjusted to suit different production cycles.

Easy Integration: This machine can be integrated with subsequent equipment (such as automatic capping machines, labeling machines, and cartoning machines) or used independently as a loading module, providing customers with flexible production line layout options.

Typical Applications and Industry Compatibility:

Laboratory Consumables Production: Automated loading of production lines for 15 mL and 50 mL centrifuge tubes, cryopreservation tubes, and sample tubes.

In-Vitro Diagnostics (IVD) and Biopharmaceutical Industries: Automating the loading process for centrifuge tubes, critical disposable consumables, effectively increases production capacity while ensuring cleanliness and consistency.

Medium to large-scale automated packaging production lines: When centrifuge tubes need to enter the automatic boxing, sealing, and labeling stages, the loader can serve as a front-end module to provide stable and high-speed feeding guarantees for the entire line.

Technical parameters:

Equipment Model: GST-LXG103A

Centrifugal tube capacity: 1-50ml

Sizes: L800*W800*H1700(mm)

Production Capacities: 250pcs/min

Power (Output): 1.5kw

Customized Support: Yes

Copyright © GuanShenTai Automation