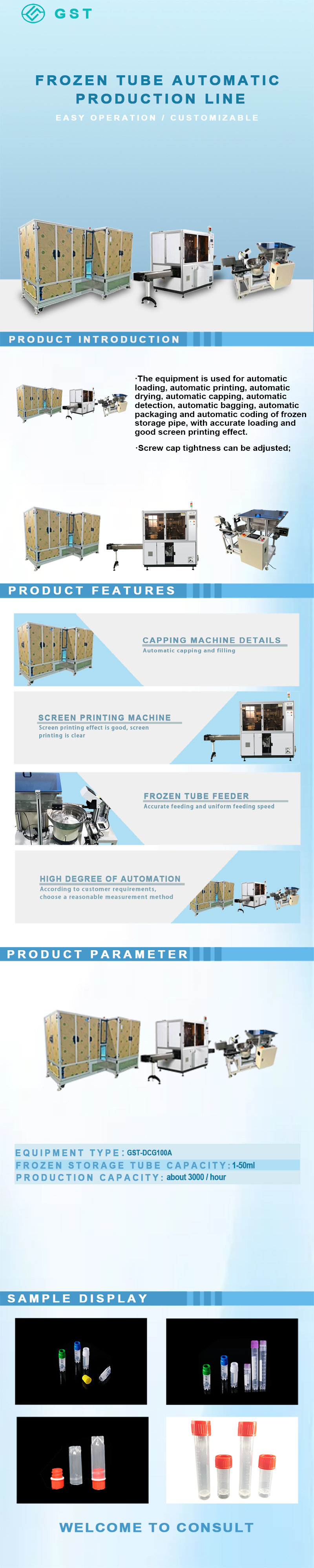

The freezing tube automatic production line is a comprehensive system integrating mechanical transmission, automatic inspection, and intelligent control. It is specifically designed to fully automate the freezing tube production process, from product loading, screen printing, printing, capping, assembly, packaging, coding, and labeling.

Main Functions and Structural Features

Automatic Loading System: Neatly arranges the injection-molded tubes and transports them to the next process.

Visual Inspection System: Uses a high-speed industrial camera to inspect the tubes for defects such as deformation, cracks, and discoloration in real time.

Automatic Printing or Laser Coding System: Marks the tubes with information such as batch numbers, scales, and QR codes.

Automatic Labeling System: Accurately applies labels to the tubes, ensuring the integrity and clarity of the information.

Automatic Assembly and Capping System: Automatically assembles the tubes and caps and caps them, ensuring a tight seal.

Automatic Packaging System: Automatically packages the finished freezing tubes for shipment.

This automatic production line is widely used in life sciences, clinical medicine, biopharmaceuticals and other fields. It is mainly used for the manufacture and quality inspection of cryopreservation tubes to meet the production needs of high efficiency and high consistency.

Technical parameters:

Equipment Model: GST-DCG100A

Freezing tube capacity: 1-50ml

Sizes: 3600*8 800*1800mm

Production Capacities: <2880 Pcs/hour 15ml: 50 Pcs/bag50ml: 25 Pcs/bag

Power (Output): 3KW

Customized Support: Yes

Copyright © GuanShenTai Automation