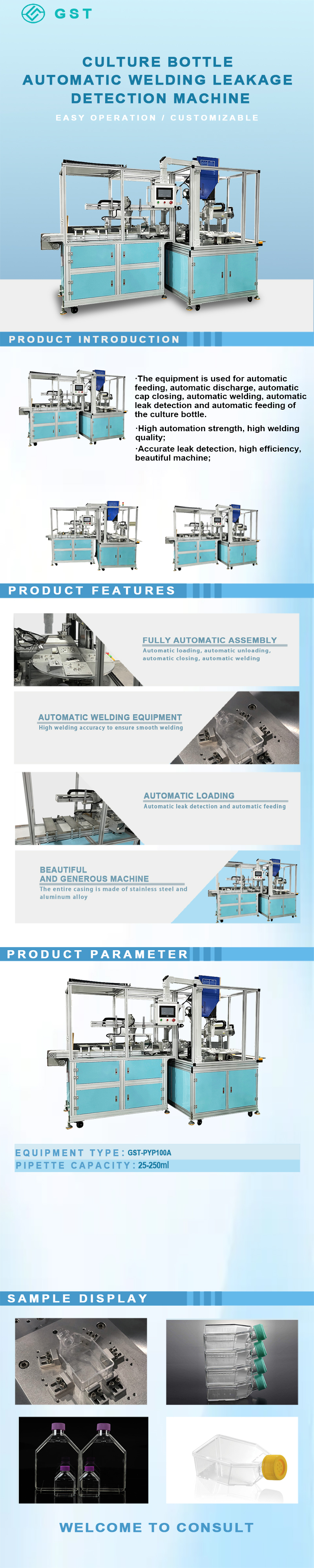

The Automatic Ultrasonic Welding Leak Detector for Culture Bottles is an intelligent device that integrates automatic feeding, ultrasonic welding, airtightness testing, and automatic sorting. It is designed specifically for the production and quality inspection of laboratory culture bottles. This equipment efficiently welds and inspects the seals of culture bottles, ensuring product quality complies with medical industry standards such as GMP and ISO 13485.

Main Functions and Structural Features

Automatic Feeding and Positioning: Culture bottles are transported to designated locations in an orderly manner via a vibrating plate or conveyor belt and automatically positioned to ensure welding accuracy.

Ultrasonic Welding Technology: Utilizing high-frequency ultrasonic vibrations, the plastic material at the weld point is instantly heated to a molten state, achieving fast and secure welds while avoiding the deformation and contamination associated with traditional thermal welding.

Airtightness Testing System: Equipped with a high-precision airtightness testing system, the equipment monitors the seal of each culture bottle in real time to ensure leak-free and consistent product quality.

Automatic Sorting and Alarm Function: Passing and failing products are automatically sorted, and alarms are automatically issued in the event of anomalies, reducing manual intervention and improving production efficiency.

Intelligent Control System: Utilizing a PLC control system and touchscreen interface, this system is easy to operate, supports data logging, and remote monitoring, meeting the demands of modern production lines.

Application Scenarios and Industry Compatibility

Laboratory Consumables Production: Suitable for the production and quality inspection of laboratory culture bottles, meeting the requirements of high cleanliness and high efficiency.

Pharmaceutical and Biopharmaceutical Industry: Compliant with GMP and ISO13485 and other medical industry standards, it is suitable for the production and quality inspection of medical devices and biopharmaceutical products.

Research and Testing Institutions: Improves the production efficiency and quality consistency of laboratory culture bottles, meeting the needs of research and testing institutions for high-quality consumables.

Technical parameters:

Equipment Model: GST-PYP100A

Freezing tube capacity: 25-250ml

Sizes: L2550*W2000*H1500(mm)

Production Capacities: 600pcs/h

Power (Output): 1.5kw

Customized Support: Yes

Copyright © GuanShenTai Automation