The automatic pipette tip cartoning machine is an intelligent device that integrates automatic feeding, cartridge insertion, cartoning, capping, and inspection, designed specifically for laboratory consumables manufacturers. It automatically arranges pipette tips into cartons according to the specified number and precisely inserts the filter cartridges to ensure product cleanliness. The machine utilizes a PLC control system and visual inspection technology, achieving high-speed and stable automated operation, reducing manual labor and improving production efficiency and quality consistency.

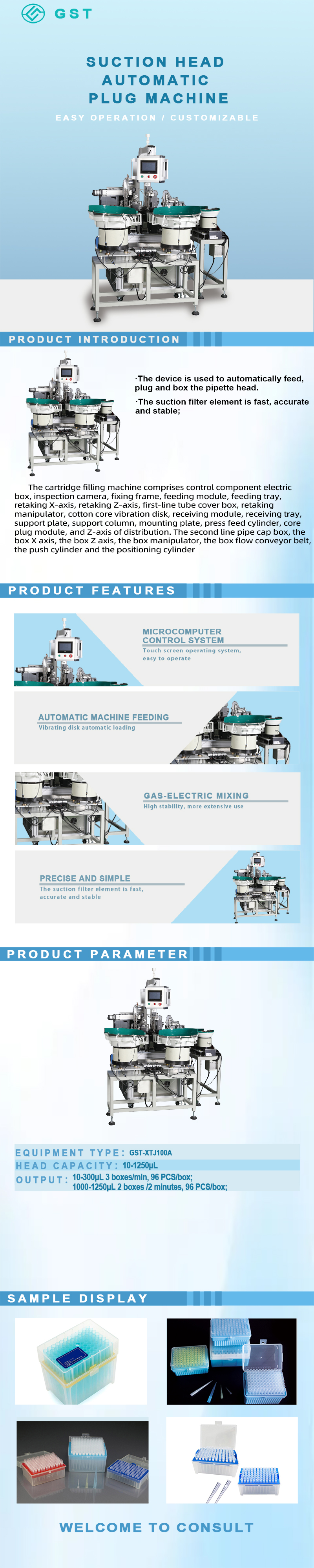

Main Functions and Structural Features:

Automatic Feeding and Sorting: Tips are transported to designated locations in an orderly manner via a vibrating plate or conveyor belt and automatically arranged. A built-in precision robot or vacuum system arranges the tips for accurate placement in the packaging.

Precision Cartoning and Packing: The system uses precise pneumatic or mechanical mechanisms to securely insert a fixed number of tips into the packaging box, preventing breakage or displacement.

Capping and Inspection: After boxing, the machine automatically caps the tubes and uses a visual inspection system to ensure the integrity and seal of each box, complying with medical industry standards such as GMP and ISO13485.

Intelligent Control System: Utilizing a PLC control system and visual inspection technology, this system achieves high-speed and stable automated operations, reducing manual labor and improving production efficiency and quality consistency.

High Efficiency and Stability: Traditional manual insertion and boxing processes are inefficient and lack consistency, while automated equipment can achieve speeds of hundreds of tubes per minute and operate stably, making it suitable for high-volume production.

Integrated Solution: Integrating loading, inserting, boxing, capping, and inspection functions into a single system, it reduces equipment space and manual interaction, improving overall production line efficiency.

Strong Scalability: Supports multiple pipette tip sizes (e.g., 10μL, 200μL, 1000μL) and quick switching between different filter cartridges to meet diverse production needs.

Application Scenarios and Industry Compatibility:

Laboratory Consumables Manufacturing: Suitable for the production and packaging of pipette tips, meeting the high cleanliness and efficiency requirements.

Pharmaceutical and Biopharmaceutical Industries: Compliant with GMP and ISO 13485 standards, suitable for packaging medical devices and biopharmaceutical products.

Research and Testing Institutions: Improves production efficiency and quality consistency of laboratory consumables, meeting the high-quality consumables needs of research and testing institutions.

Technical parameters:

Equipment Model: GST-XTJ100A

Pipette tip capacity: 1-1250μL

Sizes: L2600*W2600*H2200 mm

Production Capacities: 11000-12000 pcs/hour

Power (Output): 0.7KW

Customized Support: Yes

Copyright © GuanShenTai Automation