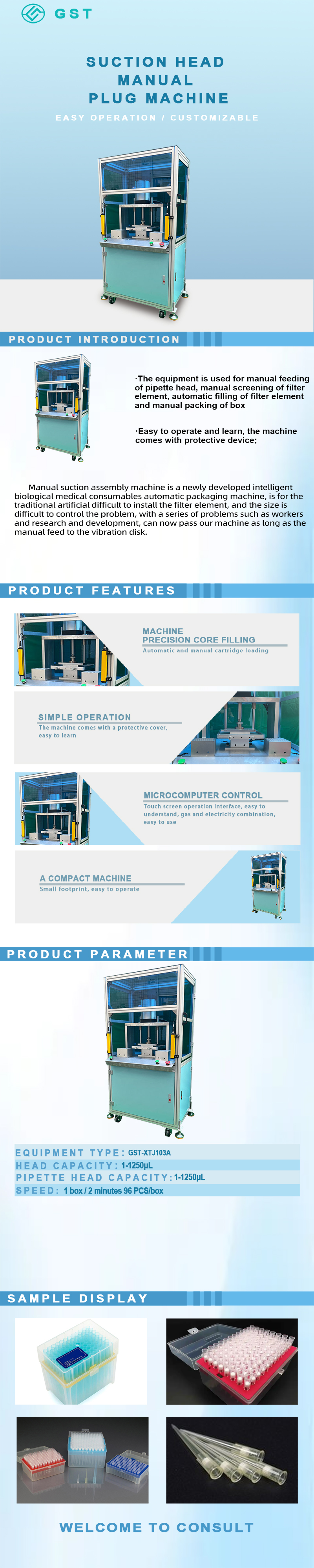

The semi-automatic pipette tip cartridge cartoning machine is designed specifically for laboratory consumables manufacturers. It is primarily used for inserting cartridges (cores) and integrating them into the carton during the pipette tip cartoning process. The machine operates semi-automatically, meaning that with manual assistance, it automatically completes tip cartridge positioning, loading, assembling the cartridge, and integrating it into the case, providing users with an efficient, accurate, and stable cartoning solution.

Key Functions and Structural Features:

It quickly adjusts to accommodate different tip racks, cartridges, or cartridges, supporting small batches and multiple product varieties, enabling manufacturers to flexibly respond to market changes.

Automating the cartoning process significantly reduces manual effort, operational errors, and rework, thereby improving overall production line efficiency.

Equipped with a PLC and touchscreen control system, parameters (such as tip specifications, core dimensions, carton quantity, and speed) can be set and quickly switched, adapting to multi-specification, small batch, or variable product production environments.

Constructed with a stainless steel/aluminum alloy frame and a protective transparent cover, it meets clean manufacturing requirements. Key contact areas with tips and cartridges are removable for easy cleaning, meeting the cleanliness and zero-contamination requirements of the laboratory consumables industry.

The compact, modular design reduces operator effort, simplifies maintenance, and allows for rapid format changeover. It is ideal for medium- to large-scale consumables manufacturers seeking to automate their cartoning process, reduce labor intensity, and improve consistency.

Application Scenarios and Industry Compatibility

It is suitable for the "pipet (or inner cartridge) insertion and cartoning" steps in pipette tip production lines, a common practice in laboratory consumables manufacturing.

It is suitable for small- to medium-scale production of products such as pipette tips, reagent tubes, and micropipette accessories requiring efficient cartoning in IVD, life sciences, biopharmaceuticals, and laboratory tool manufacturing.

When production specifications fluctuate, changeovers are frequent, and cartoning accuracy and cleanliness are critical, this device can effectively replace traditional manual cartoning, improving efficiency, reducing defective product rates, and enhancing product consistency.

Technical parameters:

Equipment Model: GST-XTJ103A

Sizes: 360*320*5250px

Tip capacity: 1-1250μL

Production Capacities: 1 box/minute 96 pcs/box

Power (Output): 1.5kw

Customized Support: Yes

Copyright © GuanShenTai Automation