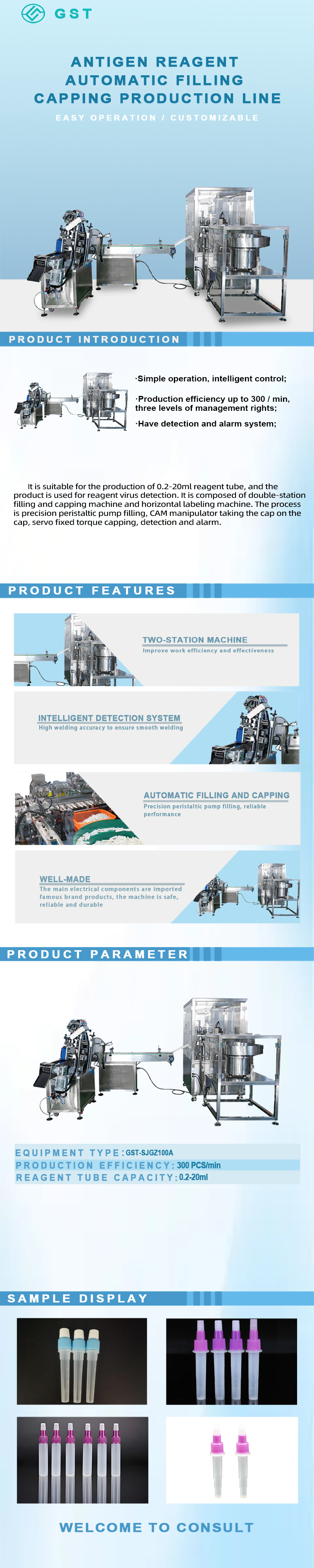

The antigen reagent automatic filling and capping line, designed specifically for the in vitro diagnostic (IVD) industry, provides a fully automated solution from reagent filling, capping, labeling, to packaging. This modular line supports a variety of antigen reagent vials, meeting the requirements for efficient, precise, and clean production. It is widely used in the production of antigen reagents, ELISA plates, test kits, and other products.

Core Functions and Process Flow:

Automatic Bottle Loading and Positioning: The system automatically feeds empty vials into the line using a vibrating plate or robotic arm and precisely positions them, ensuring the vial mouth faces upward, ready for filling.

High-Precision Liquid Filling: A multi-channel filling head, combined with vision recognition technology, achieves quantitative filling for each vial, ensuring accurate and consistent liquid volume.

Capping and Pressing: After filling, the cap is automatically fed into the vial mouth and tightly sealed by the capping mechanism to prevent leakage and contamination.

Labeling and Sorting: The system automatically applies labels with information such as batch number and production date, and a visual inspection system verifies label placement and quality to ensure label accuracy.

Automatic Packaging and Discharging: After completing the above steps, the product automatically enters the packaging area for cartoning and sealing, and is finally discharged through the discharging port, completing the entire production process.

Technical Features and Advantages:

High-Efficiency Production Capacity: The entire production line can achieve a production speed of up to dozens of bottles per minute, meeting the needs of large-scale production.

Precision Control System: An advanced PLC control system, combined with a human-machine interface (HMI), enables precise control and parameter adjustment of each process.

Clean Design: The equipment is constructed of stainless steel and complies with GMP standards, suitable for cleanroom environments, ensuring product hygiene and safety.

Intelligent Inspection: Equipped with a visual inspection system, it monitors various indicators during the production process in real time, automatically rejects defective products, and improves product quality.

Flexible Adaptability: The production line can be customized to meet customer needs, adapting to various types of antigen reagent bottles to meet diverse production requirements.

Technical parameters:

Model Number: GST-SJGZ100A

Sizes: L3800*W1400*H1800mm

Production Capacities: 300pcs/min

Power (Output): 3KW

Reagent Tube Capacity:0.2-20ml

Customized Support: Yes

Copyright © GuanShenTai Automation