Dental mirrors (also known as dental endoscopes) are essential instruments for dental examinations and treatments. Their structure typically consists of multiple precision components, including a lens, body, connecting rod, lighting assembly, and housing. Dental mirror automatic assembly machines are designed specifically for the fully automated assembly of these high-precision, multi-component medical devices. They efficiently complete processes such as automatic part loading, precise alignment, plugging/welding/pressing, inspection, and grading and rejection within a single machine.

Core Functions and Process Flow:

Automatic Loading and Sorting: Components enter the machine via a vibrating plate, hopper, or automatic feeder and are stably transported to each assembly station.

Precise Alignment and Assembly: Mechanical positioning fixtures and vision/photoelectric inspection technologies enable precise movements such as lens insertion and body insertion, ensuring consistent assembly for each product.

Pressing/Fixing/Welding: Depending on the structural and process requirements, the machine can perform press-fitting, ultrasonic welding, heat staking, or thread spinning to secure components, ensuring strength and a tight seal.

Online Inspection and Rejection Mechanism: After assembly, the system automatically checks for mirror position, surface defects, joint strength, and misassembled parts. Any non-compliant products are automatically rejected or reworked.

Intelligent Control System: Utilizing PLC control and an HMI interface, users can set process parameters, monitor equipment status, generate alarms, and diagnose faults. The system supports batch recording and data traceability.

Key Features and Advantages:

High Precision and High Consistency: Automated assembly control allows for micron-level error control, significantly improving product yield.

Modular Design: Each functional area (loading, assembly, inspection, and rejection) is modularly designed for easy maintenance, upgrades, and customization.

Multi-Specification Compatibility: Dental mirror assemblies of varying models, sizes, and structures can be quickly adapted by replacing fixtures or adjusting the program.

Clean Manufacturing Design: Contact areas are constructed of stainless steel or corrosion-resistant materials. The compact design eliminates dust accumulation corners and is easy to clean, meeting the clean manufacturing requirements of medical devices.

Strong whole-line integration capability: It can be linked with mirror injection, module testing, boxing, packaging and other equipment to build a complete oral mirror automated production line.

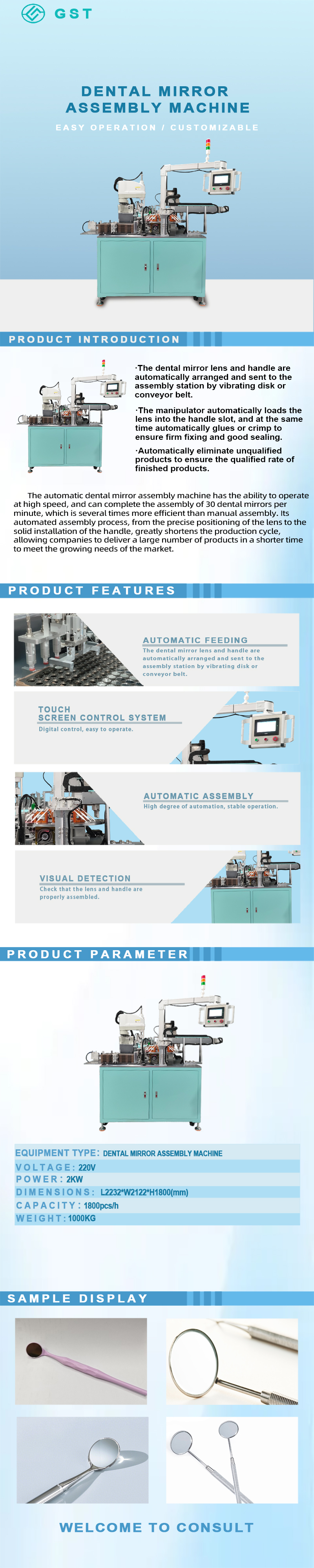

Technical parameters:

Model Number: GST-BC004

Sizes: L2232*W2122*H1800(mm)

Production Capacities: 150-200pcs/min

Power (Output): 3KW,220V

Weight:1000KG

Customized Support: Yes

Copyright © GuanShenTai Automation