Automatic labeling machines are fully automated equipment used for surface labeling of products and are widely used in industries such as food, beverages, pharmaceuticals, cosmetics, chemicals, and electronics. GST's automatic labeling machines combine high-precision mechanical structures with intelligent control systems to achieve high-speed labeling of flat, cylindrical, elliptical, and special-shaped products, meeting production line requirements for labeling speed, accuracy, and stability.

Automatic loading/conveying: Products enter the labeling station via a conveyor belt, and the equipment maintains a steady rhythm to deliver the products to the labeling module.

Vision/photoelectric positioning system: A camera or photoelectric sensor detects product position and angle, adjusting the labeling position in real time to ensure accurate labeling.

Labeling head action: The labeling head brushes or presses the label onto the accurately positioned product surface. The labeling speed is adjustable, and the angle and pressure are controlled by the system.

Peeling and applying mechanism: The label is peeled from the label tape and guided to the product surface. The labeling machine supports functions such as label angle folding and tilt compensation to enhance labeling quality.

Inspection and Rejection: After labeling, the machine uses a visual inspection system to check for label placement, missing labels, and label offset, automatically rejecting defective products.

Intelligent Control System: PLC control and a touchscreen HMI interface allow users to configure labeling parameters, operating speed, alarm thresholds, and maintenance modes.

High Precision and Repeatable Labeling Consistency: The precise mechanical structure and stable transmission ensure labeling position error within ±0.5 mm.

Strong Multi-Specification Compatibility: By replacing the labeling fixture or adjusting parameters, the machine can accommodate products of varying diameters, shapes, and heights.

High-Speed and Stable Operation: Designed for high-speed labeling, it can operate synchronously with high-speed production lines, improving overall efficiency.

Modular and Easy-Maintenance Construction: The modular design of each component facilitates installation, cleaning, and module replacement, reducing maintenance time.

Clean Design: Product-contact components are constructed of food-grade stainless steel or corrosion-resistant materials, with a smooth, easy-to-clean structure suitable for cleanroom production.

Strong compatibility with the entire line: The labeling machine can be easily integrated into automated production lines such as filling, sealing, leak detection, and packaging to achieve linked operations.

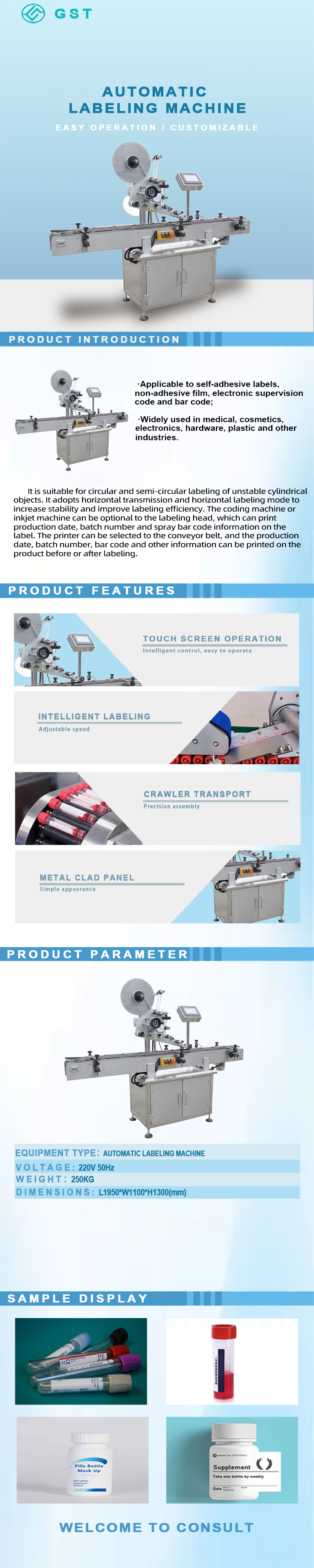

Technical parameters:

Model Number: GST-BC003

Sizes: L1950*W1100*H1300(mm)

Production Capacities: 100pcs/min

Power (Output): 220V

Customized Support: Yes

Weight: 250KG

Copyright © GuanShenTai Automation