Automatic filling machines for disposable syringes are designed specifically for filling prefilled or conventional disposable syringes, aiming to achieve high-speed, precise, and aseptic filling and capping (or plugging) operations. These machines can be integrated with modules for loading, cleaning, deactivation, sealing, and visual inspection to create a complete automated production line.

Automatic conveying and loading: Syringe components (barrels, pistons, stoppers, and injection solutions, etc.) are automatically arranged and transported to the filling station by a dedicated feeding mechanism. The system supports vibrating plates, mechanical gripping, or oscillating feeding methods to ensure stable supply.

Precise quantitative filling: High-precision flow meters, volumetric meters, or electronic weighing sensors are used to control the filling volume tolerance for each syringe to extremely small limits, preventing overfilling or underfilling.

Aseptic capping/plugging/sealing: After filling, the system automatically inserts the stopper, plugging, or seals the syringe, ensuring a tight seal and safe use. For example, prefilled syringe filling and sealing machines in the industry employ a sterile, sealed environment for both filling and capping.

Online Inspection and Rejection Mechanism: The equipment utilizes visual inspection, pressure testing, and leak detection to inspect the quality of filled syringes. If problems such as abnormal fill volume, poor seal, or misaligned stopper are detected, unqualified products are automatically rejected.

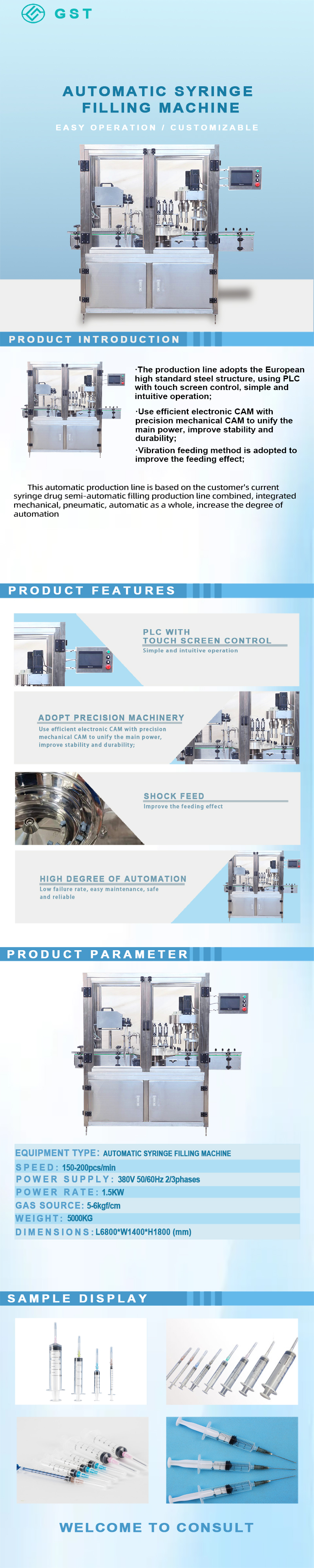

Intelligent Control System: Equipped with a PLC controller and touchscreen human-machine interface (HMI), filling parameters can be set, operating status monitored, alarms generated, and fault diagnosis provided. The system supports parameter storage, batch management, and remote monitoring.

Modular Design and Fast Switching: Each functional module (loading, filling, sealing, inspection, and rejection) utilizes a modular structure, enabling quick fixture replacement and adjustment of settings to suit different specifications or product models.

Clean and Hygienic Design: Components contacting liquids or near syringe components are constructed of stainless steel or medical-grade materials. The compact design is easy to clean and eliminates dead corners, making it suitable for clean environments that meet GMP or ISO pharmaceutical production requirements.

This automatic filling machine is suitable for producing a variety of disposable syringes (such as vaccines, pharmaceuticals, and diagnostic fluids), particularly those requiring high filling accuracy, sterility, and tightness. By introducing this equipment, companies can significantly increase filling speed, reduce manual errors, mitigate the risk of cross-contamination, and enhance overall line automation.

Technical parameters:

Model Number: GST-BC001

Power supply: 380VAC, 50/60Hz, 2/3 phase.

Power: 1.5kw

Working speed: 150-200pcs/min

Machine weight: 5000kg

Air source: 5-6kgf/cm².

Overall Dimension: L6800*W1400*H1800mm

Customized Support: Yes

Copyright © GuanShenTai Automation