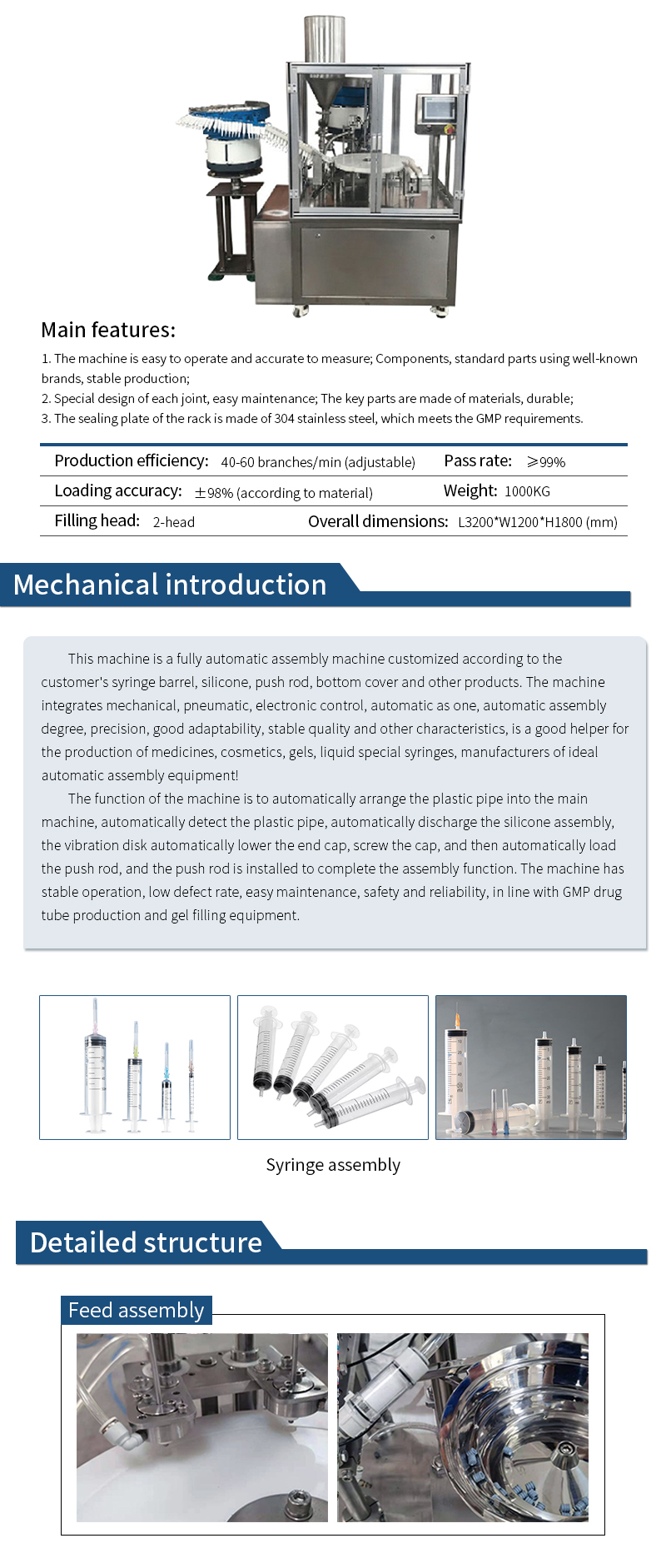

Product Description:

This machine is a full-automatic assembly machine customized according to the customer's syringe barrel, silicone, pusher, bottom cap and other products. The machine integrates mechanical, pneumatic, electric control and automatic as a whole, with high degree of automatic assembly, accurate precision, good adaptability, stable quality and other features, it is a good helper for the production of special syringes for pharmaceuticals, cosmetics, gels and liquids, and an idealized automatic assembly equipment for manufacturers!

The machine function is to automatically arrange the plastic tube into the main machine, automatic detection of plastic tubes, automatic discharging silicone assembly, vibration plate automatically under the end cap, screw the cap, and then automatically loaded into the pusher, the pusher is loaded to complete the assembly function; the machine is stable in operation, low defective rate, easy to maintain, safe and reliable, in line with the GMP medication tube production, gel filling equipment.

Product features:

1) The machine is easy and simple to operate, accurate assembly;.

2)Components and standard parts are made of famous brand, stable production;.

3)Each joint part is specially designed for easy maintenance.

4) The key parts are made of special materials, durable.

5) The rack sealing plate is made of 304 stainless steel, which meets the GMP requirements.

Technical parameters:

1)Output: 40-60 pcs/min(adjustable).

2) Loading accuracy: ±98% (according to the material distinction);.

3) Number of filling heads: 2 heads.

4)Qualified rate of finished products: ≥99%.

5)Power supply: 220V, 50Hz.

6)Air pressure: 0.3Mpa~0.4Mpa.

7)Overall dimension: 3200*1200*1800.

8)Weight: about 1000KG.

Copyright © GuanShenTai Automation