Product Description:

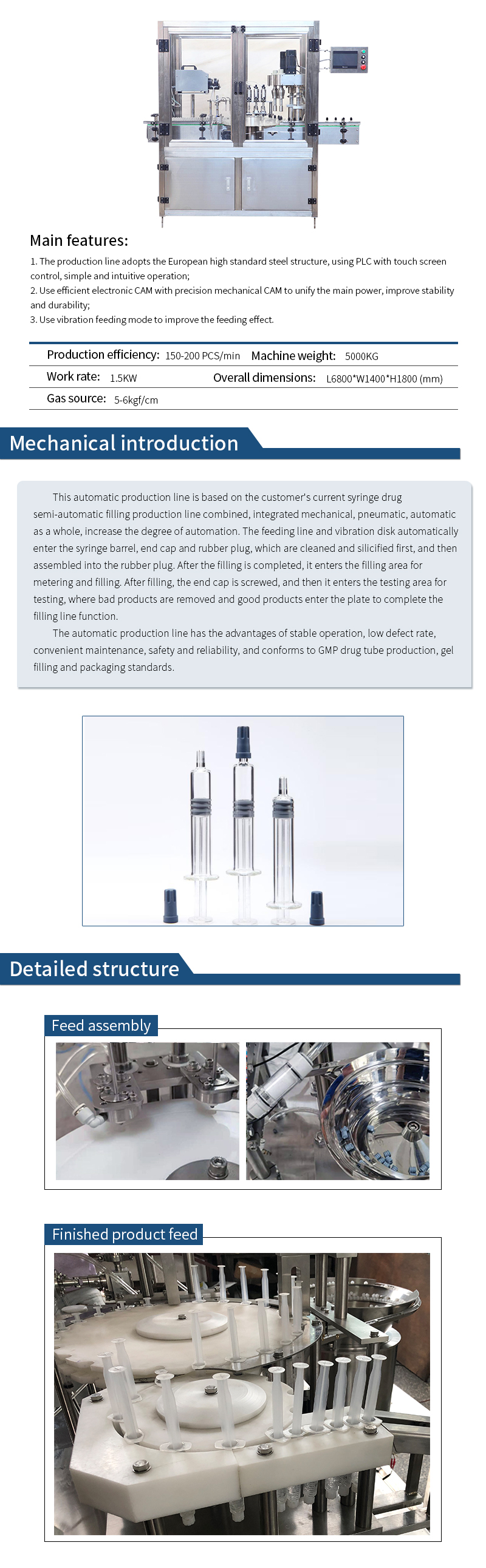

This automatic production line is based on the customer's current syringe drug semi-automatic filling production line combined and become, integrated mechanical, pneumatic, automatic as a whole, to increase the degree of automation; from the feeding line and vibration plate automatically into the syringe barrel, end cap, plug, first after cleaning, siliconization, and then plug assembly, completed and then enter the filling area for metering and filling, filling and then followed by screwing the end cap, and then enter the detection area for detection, bad products into the sterilization tray loading tray, automatic finished products, complete the function of the filling line. After that, it enters the filling area for metering and filling, filling and then screwing the end cap, and then enters the testing area for testing, rejecting the defective products, and then the good products enter the sterilized tray for loading, and then the automatic finished products complete the function of the filling line.

The automatic production line is stable, low defective rate, easy maintenance, safe and reliable, in line with the GMP standards for the production of drug tubes and gel filling and packaging.

Machine features:

1)The production line adopts European high standard steel structure;.

2) PLC with touch screen control, simple and intuitive operation.

3)Unify the main power with high efficiency electronic cam and precision mechanical cam to improve the stability and durability; 4)Adopt vibration feeder; 5)Adopt high efficiency electronic cam with precision mechanical cam to improve the stability and durability.

4)Adopt vibration feeding method to improve the feeding effect.

Technical parameters:

Power supply: 380VAC, 50/60Hz, 2/3 phase.

Power: 1.5kw

Working speed: 150-200pcs/min

Machine weight: 5000kg

Air source: 5-6kgf/cm².

Overall Dimension: L6800*W1400*H1800mm

Copyright © GuanShenTai Automation