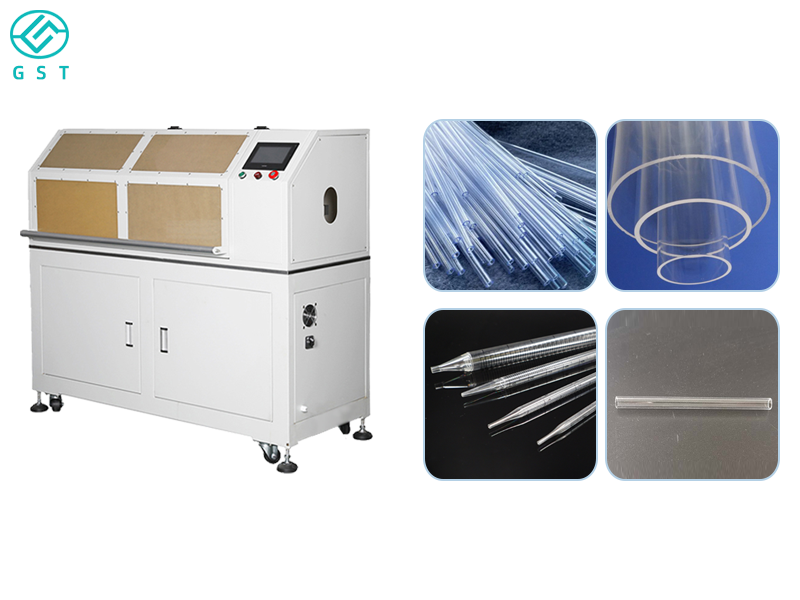

Automated Cutting Equipment: A highly efficient and precise manufacturing tool

In today's manufacturing industry, automated cutting equipment has become synonymous with efficiency, precision, and time and labor savings. It is an advanced device that automatically completes material cutting according to a preset program, significantly improving production efficiency and cutting accuracy, bringing about revolutionary changes to various industries.

1. Characteristics of Automated Cutting Equipment

Automated cutting equipment integrates modern computer technology, mechanical technology, optical technology, and other multidisciplinary knowledge, and has the following characteristics:

High degree of automation: Through preset programs, automated cutting equipment can independently complete material identification, cutting, and sorting operations, greatly reducing manual intervention.

High cutting precision: Using advanced laser, water jet, and other cutting technologies, it can complete high-precision cutting operations in a short time.

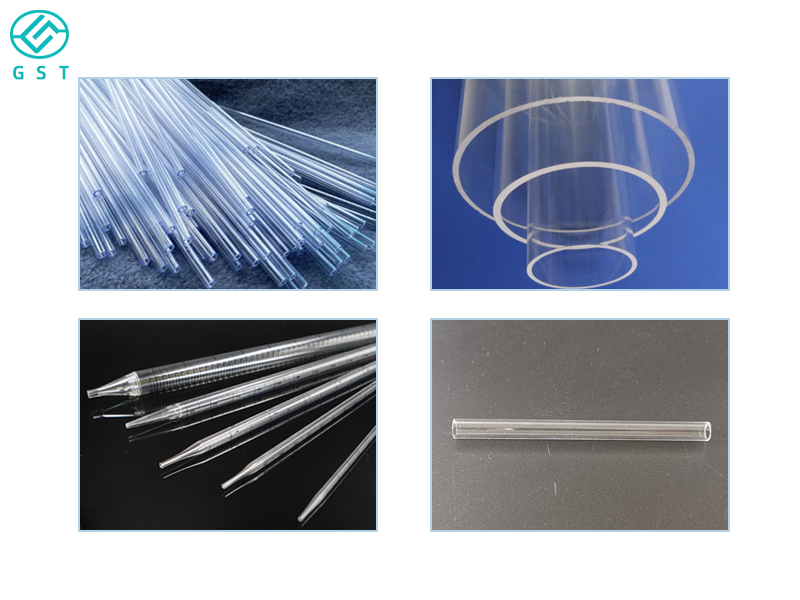

Wide range of applications: Suitable for various materials, such as metals, non-metals, and composite materials.

Saves time and labor: Automated cutting equipment can significantly improve cutting efficiency, reduce working hours, and lighten the burden on workers.

2. Application Principles and Operating Methods of Automated Cutting Equipment

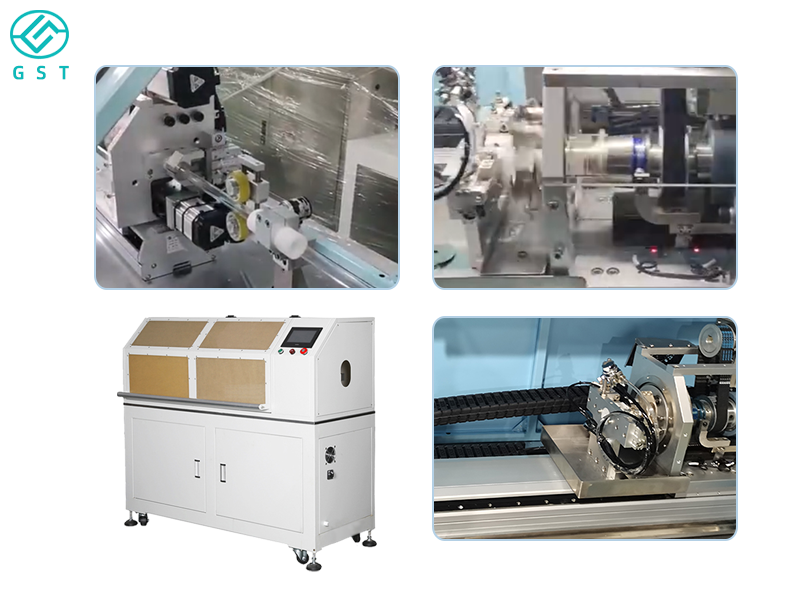

The application principle of automated cutting equipment is mainly to control the cutting head for high-speed and precise cutting through computer technology. The operation method is simple: simply place the material to be cut on the equipment's worktable, input the corresponding cutting program and parameters, and the equipment will automatically complete the cutting operation.

During operation, common problems with automated cutting equipment include cutting head blockage, improper material placement, and errors in the cutting program. To solve these problems, operators need to regularly inspect and clean the cutting head, ensure that the materials are placed neatly, and be proficient in adjusting the cutting program and parameters.

3. Advantages of Automated Cutting Equipment

Compared with traditional cutting equipment, automated cutting equipment has the following advantages:

High efficiency: Automated cutting equipment can significantly improve cutting efficiency and shorten production cycles.

High precision: Using advanced cutting technology, it can achieve high-precision cutting and improve product quality.

Time saving: Reduced manual intervention saves a significant amount of time.

Labor saving: Automated cutting equipment can reduce the burden on workers and lower labor costs.

4. Widespread Application of Automated Cutting Equipment

Automated cutting equipment has been widely applied in various fields, including mechanical manufacturing, construction, and electronics. In mechanical manufacturing, automated cutting equipment can be used to process various mechanical parts, improving production efficiency and product quality; in the construction industry, it can precisely cut building materials, improving construction quality and efficiency; in the electronics industry, it can be used for cutting fine components such as circuit boards and membrane keyboards, improving production efficiency and product quality.

Taking a mechanical manufacturing company as an example, after introducing automated cutting equipment, the company achieved efficient and precise cutting of complex mechanical parts, increasing production efficiency by 30% and reducing labor costs by 20%, resulting in significant benefits.

5. Outlook for Future Automated Cutting Equipment

With the continuous development of technology, future automated cutting equipment will develop towards higher precision, higher speed, and greater intelligence. At the same time, with the rise of green manufacturing, automated cutting equipment will focus more on environmental protection and energy saving.

To promote the further development of automated cutting equipment, we suggest:

Strengthening technological research and development: Continuously exploring new cutting technologies and principles to improve the precision and speed of automated cutting equipment.

Promoting applications: Increasing publicity and promotion of automated cutting equipment to increase its application rate in the manufacturing industry.

Training personnel: Strengthening the training of operators and maintenance personnel to improve their skill levels and understanding of automated equipment.

Automated cutting equipment, as an important tool in modern manufacturing, has many advantages such as high efficiency, precision, time-saving, and labor-saving, and is gradually replacing traditional cutting equipment, becoming the preferred choice in various industries. Through a deeper understanding of automated cutting equipment, we can see its important role in improving production efficiency, reducing costs, and improving product quality.