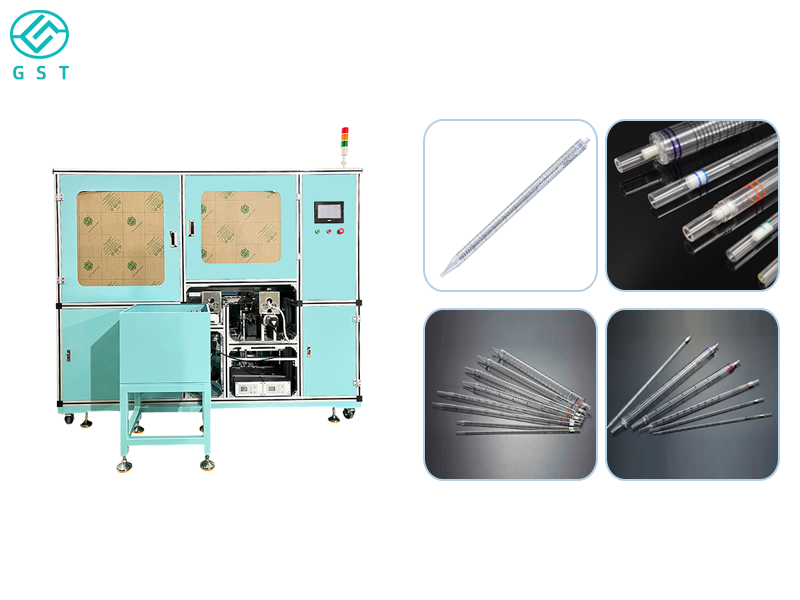

Automated Pipette Production Lines: A New Trend in Smart Manufacturing of Laboratory Consumables

In high-tech fields such as life sciences, medical testing, and biopharmaceuticals, pipettes, as fundamental yet critical laboratory consumables, have a quality and production efficiency that directly impacts research progress and testing accuracy. Against this backdrop, automated pipette production lines have emerged, becoming core equipment for industry upgrades. As a leading domestic manufacturer of intelligent laboratory consumable equipment, GST is accelerating the industry's transformation towards efficient, intelligent, and green manufacturing with its independently developed fully automated pipette production line.

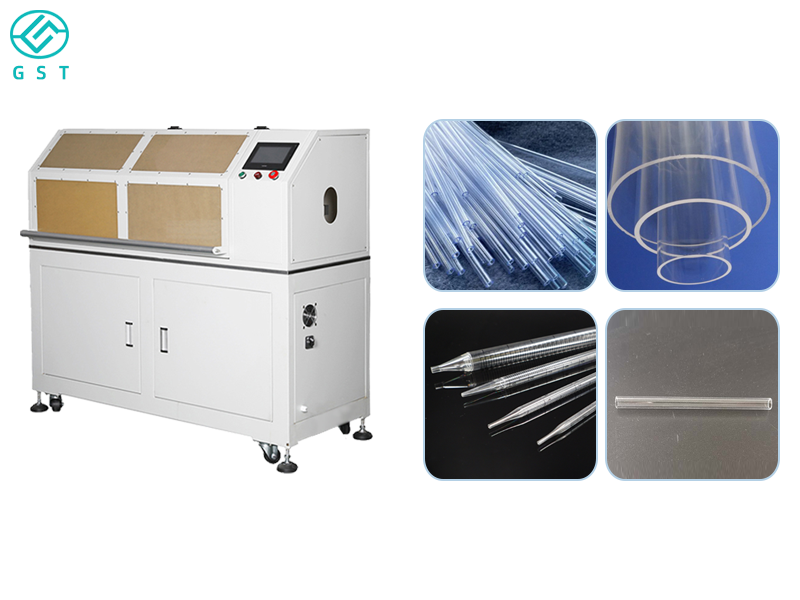

Traditional pipette production relies heavily on manual operation, which is not only inefficient but also prone to problems such as dimensional deviations and substandard cleanliness due to human factors. The fully automated production line integrates injection molding, online inspection, automatic stacking, and sterilization packaging modules, achieving "unmanned" continuous operation from raw materials to finished products. This not only significantly increases production capacity (daily output can reach hundreds of thousands of units) but also ensures high consistency in key indicators such as accuracy, transparency, and pyrogen-free properties for every pipette, fully complying with ISO 13485 and GMP certification standards.

As a high-tech enterprise with over ten years of experience in automated equipment for laboratory consumables, GST has always focused on intelligent manufacturing solutions for products such as pipette tips, pipettes, and PCR tubes. Its independently developed automated pipette production line boasts the following core advantages:

Fully closed-loop intelligent control: Using a PLC+HMI system, it monitors parameters such as temperature, pressure, and speed in real time to ensure process stability;

High-precision visual inspection: Integrating AI image recognition technology, it automatically rejects defective products such as burrs, bubbles, and oversized dimensions, achieving a yield rate of over 99.5%;

Modular and flexible design: Supports rapid switching between various pipette specifications (such as 1mL, 5mL, and 10mL), meeting customers' needs for multi-category, small-batch production;

Complies with international cleanliness standards: The entire line can operate in an ISO Class 7 (Class 10,000) clean environment, meeting the production requirements for medical-grade consumables. Currently, GST's automated pipette production lines have successfully served numerous well-known domestic and international biological consumables companies and have been exported to markets in Europe and Southeast Asia, earning widespread recognition for their high cost-effectiveness and localized service.

With the explosive growth of precision medicine and the in-vitro diagnostics (IVD) industry, the demand for high-quality pipettes will continue to rise. Choosing a stable, efficient, and compliant automated production line is not only crucial for companies to reduce costs and increase efficiency, but also a strategic cornerstone for capturing the high-end market. GST will continue to invest in R&D to provide customers with one-stop intelligent factory solutions, from equipment delivery to production line operation and maintenance.