Advantages of non-standard automation manufacturers and industry trends

Off-standard automation manufacturers play a crucial role in modern industrial development. Compared with standardized automation equipment, the customization, flexibility and adaptability of off-standard automation equipment meets the specific needs of different enterprises, helping them to optimize production processes, improve efficiency and reduce costs. In this article, we will introduce the industry status, key advantages, challenges and future trends of non-standard automation manufacturers.

I. Non-standard automation manufacturer's position in the industry

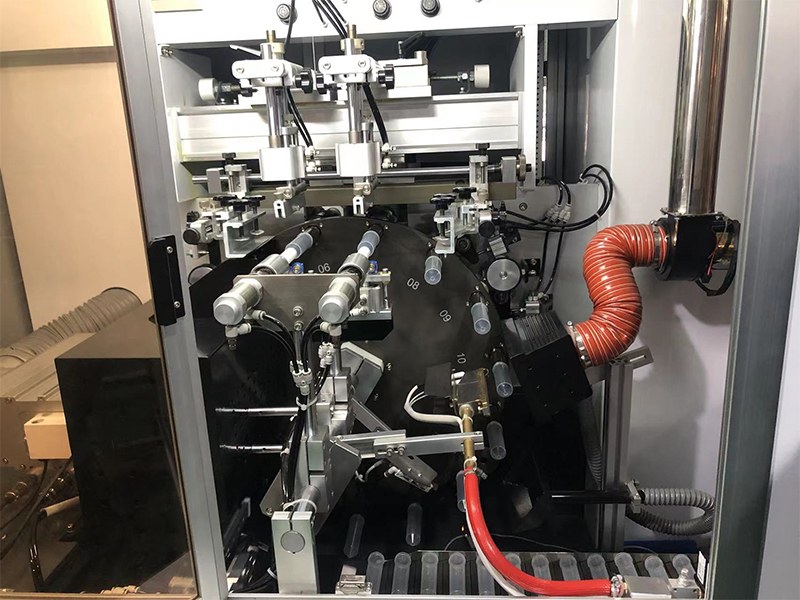

Non-standard automation manufacturers are mainly committed to providing enterprises with customized automation production equipment and solutions. They design the equipment according to the specific needs of customers, and realize one-stop service from equipment development, manufacturing to follow-up maintenance. Non-standard automation equipment has irreplaceable advantages in the production process, especially in the fields of industrial manufacturing, food processing, electronic product production, medical device manufacturing, and auto parts manufacturing. With the promotion of intelligent manufacturing and industry 4.0, enterprises have higher and higher requirements for automation, precision and efficiency of production, which has promoted the development of non-standard automation manufacturing industry.

Second, the main advantages of non-standard automation manufacturer

1. Highly customized: the primary advantage of non-standard automation manufacturer is the customization of equipment. Standardized equipment is difficult to meet the production needs of some specific industries, while non-standard automation equipment can be tailored to customer needs. This high degree of customization ability to achieve equipment in the performance, size, output, intelligence and other aspects of the precise design, so that the equipment is fully adapted to the customer's production process.

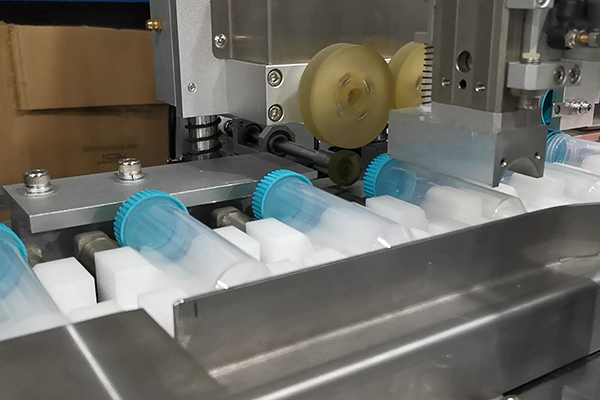

2. Improve production efficiency: non-standard automation manufacturer for the enterprise tailor-made equipment can automatically complete a variety of complex operations, shorten production time, improve overall efficiency. For example, in the electronics manufacturing industry, non-standard automation equipment can complete the automatic placement of precision components and testing, significantly reducing manual operation, improve production line efficiency and product consistency.

3. Flexibility and adaptability: non-standard equipment can be adjusted to changes in production requirements. Many manufacturers in the design of non-standard equipment will take into account the future expansion needs, this flexible design allows companies to flexibly respond to market changes, and in the premise of not replacing the equipment to achieve the production of different products.

4. Quality and precision guarantee: As the non-standard automation equipment is carefully designed according to the customer's specific process requirements, it has high-precision and high-quality production capacity, avoiding errors and product inconsistencies brought about by human operation. The equipment uses intelligent control systems (e.g. PLC control, image recognition and sensor systems) to monitor each production step, thus ensuring product quality and consistency.

5. Reduced labor costs: Automation equipment provided by non-standard automation manufacturers significantly reduces the need for human involvement, especially in scenarios that require long hours of repetitive work. Manufacturers are able to reduce labor costs through non-standard automation equipment, and improve efficiency while reducing the safety risks of labor-intensive operations.

Third, the challenges faced by non-standard automation manufacturers

Although non-standard automation manufacturers have many advantages in customized equipment, but the industry is also facing many challenges:

1. R & D and technical difficulties: the development and design of non-standard equipment is relatively complex, requiring the integration of a variety of technologies, including mechanical design, electrical control, programming and so on. This not only requires manufacturers to have strong technical R&D capabilities, but also requires extensive industry experience and engineering knowledge. In particular, some high-precision or high-difficulty equipment has extremely high technical requirements, long R&D cycles and high costs.

2. Unstable demand: Since the non-standard equipment is completely based on customer demand design, its demand is unstable, affected by the market environment, customer budgets, technical requirements and other factors. Fluctuations in the number of orders is easy on the manufacturer's production capacity scheduling and capital turnover pressure.

3. Intense market competition: non-standard automation industry has attracted more and more enterprises to participate in the competition, the market is gradually becoming saturated. For some new entrants, the lack of technical advantages and customer base, making it difficult to quickly stabilize the market. And there are manufacturers also need to continue to invest resources in technology research and development and market development, in order to maintain a competitive advantage.

Fourth, the future development trend of non-standard automation manufacturers

Non-standard automation manufacturers are gradually moving towards the direction of intelligence, data and globalization:

1. Intelligent manufacturing: intelligent manufacturing is the core direction of the future development of non-standard automation industry. More and more non-standard equipment manufacturers are combining artificial intelligence technology, intelligentizing the control, management, monitoring and other functions of the equipment, realizing self-diagnosis and adjustment of automation equipment, and improving production efficiency. At the same time, intelligent non-standard equipment can also realize data connectivity between equipment and optimize the production process through big data analysis and Internet of Things technology.

2. Flexible production line development: with the diversification of customer needs, companies need to produce a variety of products to adapt to rapid changes in the market. Non-standard automation manufacturers began to design and develop flexible production lines, so that the equipment can be quickly adjusted to produce different products. Flexible equipment not only enhances the adaptability of the production line, but also allows companies to make different batches of products without replacing the production line.

3. Energy saving and environmental protection: non-standard automation manufacturers will pay more attention to energy saving and environmental protection design in the future. Energy-saving equipment and low energy consumption can not only reduce production costs, but also meet the requirements of modern society on environmental protection. Some non-standard equipment manufacturers are developing new environmentally friendly materials, or optimize the power consumption of equipment to provide customers with sustainable automation solutions.

4. Internationalization: With the advancement of non-standard automation technology, more and more manufacturers are setting their sights on the international market, especially the developed countries and emerging economies with greater demand for automation. The layout of globalization not only helps enterprises to explore the market, but also in the international competition to obtain technology and management experience, laying the foundation for future development.

5. After-sales service and maintenance management: the complexity of non-standard automation equipment requires manufacturers to provide perfect after-sales service, the future of non-standard automation manufacturers may be more remote monitoring and online diagnostics, to improve the efficiency of equipment maintenance and management. At the same time, non-standard equipment based on intelligent technology can also realize self-maintenance through system updates, thus extending the service life of the equipment.

Non-standard automation manufacturers play an important role in modern industry, providing quality production solutions for enterprises in different industries by virtue of their high degree of customization, flexibility and high precision. Despite the challenges of technological research and development, market volatility and competition, the future of the non-standard automation industry remains bright. Driven by the trends of intelligent manufacturing, flexible production, energy saving and internationalization, non-standard automation manufacturers will continue to innovate and upgrade to provide more advanced automation equipment and services for various industries.